Note the bold move, starting a new page titled "Finishing the Boat". I intend this to get myself into the mindset of actually, finally, finishing the boat.

May 11, 2024: I have done nothing on the boat since last summer, nothing. Instead, I foolishly returned to school. I started with one easy course, Intro to AI. No problem. So then, this past semester I took two courses, Machine Learning, and a grad seminar in cognitive psychology. Problem. That was a lot of work. A ton of reading for the grad seminar; and for the other course, a lot of math (mine is rusty), and getting used to a very different kind of programming. Anyway, that's done. So now I need to get back to the boat. Once again, I'm aiming to get the boat into the water this summer. The hull is done, so how hard could it be?

July 6, 2024: I did not get back to the boat, back in May, when I said "I need to get back to the boat" (paragraph directly above). Here are my excuses:

Anyway, I've been busy, and I'm just getting back to the boat now, finally. Actually, I started a few days ago, at which point I discovered that my resin pump was not working, and my backup pump was also not working. I ordered new supplies, and finally FINALLY got back to it today. I glued the mast together, and continued sanding/epoxying the rudder and centerboard. (You really don't need to see pictures, it looks just like many of the other pictures. I will strive for more original content in the coming days.)

The boat will not be ready when Julia arrives, in six days. Hopefully this summer. Otherwise it gets even more embarrassing for me. (I'm in year five of this project right now.)

July 7, 2024: More epoxy and sanding. And I started epoxying

the spars.

See? I could have just duplicated some earlier pictures and you wouldn't have noticed. Although, a truly alert reader would notice that a new part has made its debut. On the bottom of the first picture above is the yoke. The rectangular opening fits onto the top of the rudder assembly. (And yes, it actually does fit, after some sanding.)

In other boat news, (involving boats that have actually encountered water):

The propeller looked something like that, and unlike the T-1000, did not heal instantly.

Boats are fun! That must be why I'm building another one!

I glued the mast together, and bought my very own router to round the edges of the mast. I researched routers, picked one out, and bought it. I made sure that the bit I needed was not too wide for the router, to avoid a problem I've already encountered. I read the manual and set to work.

The routing started out just fine, I was getting a nice rounded

edge on the mast. Then I noticed that the router was cutting way too

deeply into the mast.

I have written to the forum to ask if I've destroyed my mast. I

have consulted the router manual, and found the one step that

I missed, causing the bit to operate like the slide of a trombone.

Laszlo responded on the forums. There is good news and bad news. The good news is that this is fixable. Restore the routed out pieces with wood flour and epoxy, and then wrap with fiberglass. Well within my capabilities.

The bad news: I used the wrong kind of epoxy to glue the mast pieces together. Plain epoxy instead of epoxy/silica. I will phone CLC tomorrow and order new mast pieces. Wow, this is a major screw up, even by my standards.

July 10, 2024: I called CLC support, and talked to Terry, the guy who helped me early on. Terry talked me off the ledge. The epoxy without silica is fine. Don't worry about the butchered mast, it will be strong enough. As Laszlo (helpful guy on the forum) said: It's just a Skerry, you don't need to worry about it standing up to the wind going around the Horn. Technically correct, but honestly that stings a little. Still, I'll be happy to move on after only a relatively small penalty for these two errors.

I mixed up some (organic) peanut butter consistency epoxy/wood

flour and filled in the gouges.

I also did more sanding and epoxying of the boom, yard, yoke, and now the tiller. Back to routing the mast tomorrow, now that I've debugged how to use this new router.

July 14, 2024: Catching up on a few days of work. First, I

finished repairing the mast, adjusted my router the right way,

and finally finished the mast.

Routing created a lot of sawdust. That's not extremely thick blond hair

on my left arm, that's sawdust.

Then I connected the rudder and yoke.

The metal bracket and duct tape are there to ensure I have a right angle while

the epoxy sets.

After the epoxy set:

And then it's been a lot of epoxying and sanding. On the CLC forums, I got some advice on my damaged mast. Among the comments, Laszlo said to apply epoxy very lightly. This finally got through to me. The usual procedure for epoxying something is:

I.e., increasingly fine sandpaper. The idea is to be left with a few layers of epoxy and a slightly rough surface for finishing with paint or varnish. But my attitude has always been "more epoxy more better", and "epoxy solves all problems". This works against the above recipe because there is so much epoxy that it runs, and then I have to sand very heavily to remove them, which ends up removing all the epoxy I applied. This has been particularly bad with the spars (mast, boom, yard — long thin wooden pieces that support the sail).

So I finally heard the advice, used a foam brush instead of bristle, and applied

epoxy very, very lightly, to two sides, and then set the pieces aside.

This worked really well! Almost no runs, and the runs that did occur were much smaller and thinner than usual, so they were easy to fix.

In other news, I've been trying to figure out whether to varnish the boat or paint it. Everyone (me, family) prefers varnish, so that the wood grain (and all my errors) are visible. But I'm getting the impression that that is less maintainable, and a lot more work. Still researching.

July 17, 2024: Could it be? I'm actually finished buying and applying epoxy? It may actually be true. I have epoxied the inside and outside of the boat, more than I should have. I have epoxied the rudder and centerboard and tiller. The mast, boom, and yard have three coats. There is nothing else to epoxy! Which is good, because I really don't like epoxy. (Of course, once I start varnishing, I may look back on my epoxying days with nostalgia.)

Now I need to sand everything with fine (220-grit) sandpaper, to get the surface uniformly rough in preparation for paint and varnish. This has been difficult all along, and explains the over-epoxying of the hull. I apply epoxy, sand it, it's uneven, so I repeat and it never really gets better. My last try will be to sand by hand (not an orbital sander), as that will hopefully provide finer control. Julia has foolishly offered to help with this.

So I've placed what I hope is my last order from CLC. Lots of sandpaper, lots of primer, paint, and varnish, lots of brushes and rollers, a mask for Julia, new mask filters for me.

After the sanding, I will need to do 3-5 coats of varnish, 2 coats of primer, 3 coats of paint. And then, I'll put on the hardware and rig the sail and then, I hope, get the boat in the water this summer.

July 23, 2024: I've started sanding. Sanding by hand. Here

is what I'm dealing with.

Before I can apply primer, paint, and varnish, the surface of the

boat needs to be uniformly sanded, to a greyish color. This part of

the rail is partially like that, but the epoxy was applied unevenly,

and that needs to be fixed. Sorry, that's a passive voice "mistakes

were made" formulation. Let me try again. I botched the epoxying and

sanding by being too heavy-handed with the epoxy, and repeated rounds

of epoxying, sanding, epoxying, sanding, never fixed the problem. So I

am putting away the random orbital sander, and sanding by hand.

Julia is at the lake for two weeks, and volunteered to help me with

the sanding! So she helped me with the rails today.

We did just the rail tops and sides, to make sure that this approach (sanding block, 220-grit sandpaper) would do the job. It seems to work pretty well. Julia describes this task as tedious but satisfying. Like alphabetizing the spice rack. I think that's right, although as she is brand new to this task, and I am five years into it, we might be thinking of different amounts of tedious and satisfying.

July 28, 2024 Julia and I got a lot done. The front and rear seats are in good shape. I did the rails before she arrived. I gave up on the fillets because sanding by hand wasn't working, so I did some research. I think I have a plan that will allow me to finish sanding. The orbital sander seems useful on flat surfaces. A block with sandpaper for other surfaces and for focused work. A dremel tool to sand the messy fillets. Possibly a very thin layer of epoxy to cover the fillets afterward, (Laszlo told me about a "cosmetic fillet" product). And then I can paint and varnish. And after all that, there are a few places where I think I sanded into the wood, so they will need touchup and more sanding.

So, a lot of sanding. This summer is, once again, looking unlikely for a launch. Maybe this fall?

August 8, 2024: I haven't been slacking off, but there is absolutely nothing interesting to say or show. Shiny and uneven surfaces are being sanded to be dull and uniform. Except near the fillets, I'll have to come back to those. I ordered the decal for the name of the boat. Does that count as interesting?

March 8, 2025: Still nothing interesting to show you. Sanding, sanding, sanding. Still just sanding the interior. I think/hope that the exterior will go faster since it is a convex surface, no nooks and crannies, and started out smoother than the interior did.

This is only the second day I've been sanding in this horrible

year. Let's see: seasonal illnesses for Audrey and me, minor surgery

for Audrey, a 4-week-and-counting lower back issue for me (this is

the first time since it started that I've felt up to sanding). And

oh yeah, almost forgot, a lunatic Russian asset who happens to be

the US president is dismantling the federal government, and

destroying public health and medical research, national security,

and the post-war security arrangements in the northwestern

hemisphere of our planet, and preparing the FBI, Department of

Justice, and the military to enforce his decrees, and congress and

the supreme court seem to be okay with all of it. (Ed. note: Hannah

points out that blaming politics for the lack of progress in sanding

is "a pretty elaborate excuse". She is completely correct. The

author says, in his defense, that he was not giving excuses, but

explaining what about this year is making it so horrible. He said

that he would do an update, but Hannah advised against this.)

(Ed. note: There is no "ed.". It's just me reflecting on what I've

written.)

March 24, 2025: Okay! I am declaring victory over the sanding of the interior. I think that the exterior of the boat is pretty good — smooth surfaces, the fiberglass went on well, has minimal bubbles, the epoxy on the surfaces and in the joints between the panels is pretty good. None of this applies to the interior. I botched the fiberglass, redid parts of it, so the surfaces have all sorts of irregularities, and the fillets are very uneven. I sanded as well as I could. I have also sanded all the parts: rudder housing and blade, centerboard, spars. So on to sanding the exterior! That should be a much simpler sanding job, since it is convex instead of concave, and the surface is already pretty smooth. My goal is to finish sanding before the end of April, and then get painting and varnishing done in May and June.

March 29, 2025: Ready to sand the exterior.

June 2, 2025: I finished sanding the exterior. Time-consuming, manual, unpleasant, boring.

In other news,

I started painting the boat, starting with the

exterior. To prepare, I thoroughly cleaned the surface with rubbing

alcohol. Then I taped the rails, which I want to varnish.

Cleaning brought me up close to the surface, and rubbed my nose (almost literally) in all the imperfections. I am occasionally a perfectionist. Now that ship sailed (ha!) long ago on this project. I created unfixable imperfections from the very beginning, when I did a sloppy job gluing the puzzle joints together. But in examining every inch of the hull, I saw the many, many places where the fiberglassing wasn't so good, the epoxy wasn't sanded down enough, and so on. Honestly, I'm getting tired of this project and I want the boat done, and in the water. So I forced myself to ignore these little problems (I hope they're little), and just paint the damned boat and get it launched.

Part of my impatience (if that's the right term, after six years), is Julia breathing down my neck. She wanted to see the boat launched two years ago. Then again last year. As I keep telling her: this year for sure. So I am no longer seeking corners that should not be cut. Now I am cutting corners for real.

Julia is actually here, sitting next to me right now.

She is WFH, and applying subtle but real psychological pressure on me to finish the boat already.

I did lots of research on painting the boat: which primer and

paint, what kinds of brushes, how many coats of each, how to apply

them, and I checked in with CLC support to verify my

understanding. And then today, I got to work. The first coat of

primer is on!

The primer is white, and the paint will be off white.

I am a little sad that the beautiful wood grain is now painted over. But on the other hand, the paint does cover up many of those imperfections.

Alert readers of this blog know that I annually evaluate my progress toward decrepitude by three activites: putting in the dock at the beginning of the summer, and taking it out at the end of the summer, both assisted by Audrey; and in between, going water-skiing. Another part of my summer ritual, since the pandemic, is chauffeuring Hannah and Eloise from Brooklyn to the lake at the end of June, and then back after Labor Day.

This summer routine has been gutted. Julia, and her fiancé Jeffrey are visiting for a few days. (Julia will be back in July for a few weeks, and Jeffrey should be here for part of that.) They want to learn the ways of the lake, and to prepare for the day that they will need to maintain the house. So today all three of us put in the dock.

Julia and I lowered the dock and adjusted the legs. It went very

easily this year. She learned all the major skills: walking safely

on the dock frame, tightening and loosening the bolts holding the

legs, adjusting them using the complicated "cable come-along" tool:

And doing it all without dropping tools in the lake. Then, later in

the day, Julia, Jeffrey and I were going to put in the

boards. Normally, Audrey and I do this, and it takes about an

hour. We rest after after every 6 or 7 boards (there are 20 of them). It's

pretty exhausting. Julia and Jeffrey had this done in 15

minutes. Actually, Jeffrey said that Julia was slowing him down, so

he did most of it by himself.

So I am being pushed out of my dock duties. And I am no longer invited to serve as chauffeur for Hannah and Eloise. This year, Hannah's boyfriend, Ben, is driving them up to the lake and will stay for a few days.

Just put me out on an ice floe, in my rocker.

June 23, 2025: We are back in Maine for the summer. The dock

is in, one boat is in the lake, and it is hot.

But my work area is much cooler. The primer is on, so today I

scrubbed the primer to rough it up, and applied the first coat of paint.

From a social media viewpoint, I now realize that my color choice is disastrous. I foolishly decided to pick a paint color that would match the sail, and contrast with the lake That's fine once the boat is actually sailing. However, this blog documents the construction of the boat, and I now realize that the paint color is almost indistinguishable from the primer color (see above on this page). So while this photo represents progress, you can't actually see it.

The second coat of paint is on. I'll do one more, and then start varnishing. No photos today, because the photos after the second coat of white paint would look indistinguishable from those after the first coat.

Things I have learned about painting:

June 26, 2025: I applied the third and final coat of paint. Honestly, it looks like crap at each end. I think I did a reasonable job painting, but the runs and uneven application of epoxy make for a very uneven texture. Anyway, painting is done.

I called CLC to discuss varnishing. Other than the fact that I need

to apply 4–5 coats of varnish, it's all good news! First, the

technique and equipment is exactly the same as for painting. I don't

have to learn a new skill, make mistakes, fix the mistakes. Second,

I was worried about getting to all the hard-to-reach undersides of

seats, corners, and so on. CLC support said not to worry about

those too much. The varnish is most needed for surfaces are exposed

to the sun, for UV protection. (Ed. note: author is too dignified to

make the obvious joke here, about the other surfaces.)

June 30, 2025: I'm going to varnish the rails, interior, and

all the non-hull bits: mast, other spars, centerboard, rudder. It took some time to

get ready for all of that. First, Audrey and I removed the tape from the rails.

Even with the tape, some paint got through.

At a suitable distance, it doesn't look bad!

Back in the

days when I was applying epoxy, to the centerboard for example, I

would epoxy one side, turn it over, then do the other side. But

I'm going to be applying four coats of varnish (oy), and I don't want

to double that time. So I'm suspending the non-hull bits from the

ceiling. That way, I'll be able to do all sides at once. I've

suspended the spars with loops around the ends for now, but I'm going to

put in nails at the ends and move the loops over to the nails. (I

don't have any suitable nails at the moment.)

July 1, 2025: The cats are here for the summer, just three

of them this time: my cats, Cat5 and Moo, and Hannah's cat Eloise.

Eloise spends most of the year without other cats around, and prefers

it that way. She won this confrontation with Moo. She just glared

laser beams at Moo until he slunk away, back upstairs.

I applied the first coat of varnish today. That's a lot of work! The rails, top and bottom; the panels; the seats and their undersides; the frames; the centerboard box; and then all the things I'm suspending from the ceiling: the spars, the centerboard, and the rudder.

The varnish makes things look pretty good, and distracts from the

patchwork assembly of fiberglass pieces covering the interior bottom

of the boat.

I applied the varnish with the boat resting on the floor. Working and moving around on my knees got old fast. Tomorrow I'll raise the boat up again for the second coat. I can reach every point of the interior without too much difficulty, and it will be much easier on my knees.

The next few days will be pretty labor-intensive, as I will need to scrub all the varnished surfaces before applying each next coat of varnish. That's okay, it's getting really, really close to the end.

July 2, 2025: The second coat of varnish is on.

It is much better for my knees to do this work standing, with the boat raised off the ground. My arms are just barely long enough to reach the center of the boat, at its widest part. This information will soon be useless, as building just the one boat is sufficient.

July 3, 2025: The third coat of varnish is on. I didn't even bother

taking photos, because the boat looks just like it did after the

second coat of varnish. But I do have one photo.

I forgot to close the garage door last night, and this guy came in. I believe

this is a Luna Moth.

I'm going to do one more coat of varnish, and then apply the Floating Point Memo decal.

July 4, 2025: The fourth coat of varnish is mostly on. I left the floor without this last coat because I'm waiting for a can of Interlux InterGrip Non-Skid Additive. CLC tells me that wet varnish is extremely slippery. Adding varnish with this additive should decrease slipperiness, and if I'm lucky, it will also obscure the very ugly interior fiberglassing that I did.

July 8, 2025: I mixed the anti-skid additive with varnish

and applied it to the floor of the boat. This is momentous! The hull

is painted and varnished.

The steering bits are varnished.

The spars are varnished. (Suspending them from the ceiling didn't

work out. They kept slipping out, and it was difficult to get uniform

coverage. So I just ended up leaning them as shown.)

So now what remains is finishing up assembly of the rudder (putting together the tiller), attaching it to the boat, attaching the decal, and rigging. Yesterday, I confidently told Julia that the boat would be ready to launch when she shows up this weekend!

July 11, 2025: I have been figuring out how to finish up assembling the rudder, and attach it to the boat. We have a lot to discuss here.

Attaching the gudgeons and pintles: The gudgeons are brackets attached to the boat, which have a round collar. The pintles are brackets that attach to the rudder casing, and have pins that fit into the collars. So two pieces on the hull, two on the rudder, and it all has to fit together, with the collars and pins lined up perfectly so that the rudder can move left and right. I called CLC to make sure I understood all this, and to get ideas on how to make sure these four pieces line up correctly. Terry (I've been talking to him for years) suggested attaching the gudgeons first, with masking tape, and make sure they line up, by passing a dowel through the collars. I can do this! Then attach the pintles to the rudder, also with tape. Then when it's all good, one screw or bolt on each to allow for some give, and then put in the rest of the screws and bolts. This is formidable, but doable.

Bending the gudgeons and pintles: Here's where I'm in

trouble. The gudgeons and pintles don't conform to the parts of the

boat where they will attach. They need to be bent into shape. Here

are the lower and upper gudgeons:

Come on, CLC, this isn't even close. I could hear the regret in Terry's voice when he admitted that this wasn't easy, but with locking pliers (which I own) and a vice (which I own), it should be possible. I beg to differ. Look at how thick that metal is. A vice or locking pliers will hold a piece in place. But then I have to apply force to the other end, and bend the metal. That very thick piece of metal. And it has to be done precisely, so that the metal piece lies flush against the surfaces of the boat, so that the screws and bolts go in cleanly, and don't wobble around and destroy the surface of the boat.

Look at the lower gudgeon (first picture below). That lower hole is right near a bend in the gudgeon That piece near the collar needs to be flattened, and then there needs to be a very sharp turn so that the piece conforms to the skeg, and so that the hole is not right at the edge of the skeg.

CLC, how do you expect this to work? I've written to the forums. Terry clearly knows there is a problem here, I could just tell.

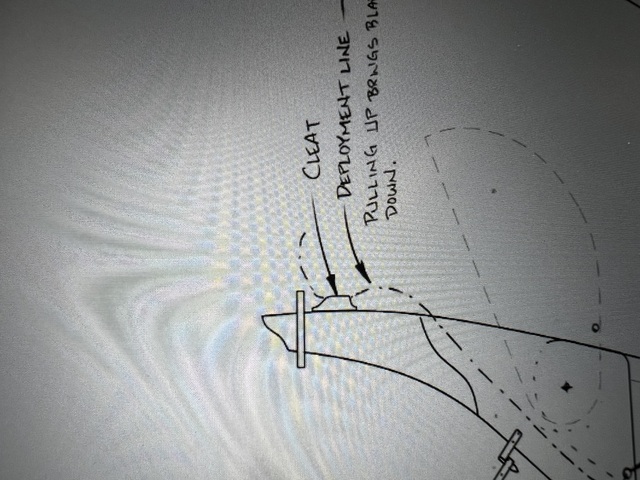

Rudder line and cleat: Then I turned my attention to the

rudder and rudder control line. This line attaches to the rudder

(which swings up and down), through the rudder casing, to a

cleat. Here is a picture from the manual. The line goes in the bottom

and out the top. The longer sloping edge of the cleat points upward.

And here is the actual cleat, oriented similarly.

But this is wrong. Note that the hole through which the rudder line

passes is at the top, and the ridged part of the cleat is below it.

I think the cleat in the diagram is upside down. I called Terry back to ask about this, and while he admitted that the diagrams are kind of sparse, and that the manual is 11 years old (and so, infallible?), he would not say whether it was wrong. I'm guessing he didn't have a Skerry cleat handy, which is understandable as CLC supports dozens of boat plans. He finally said "do whatever works". Terry has always been patient, and I'm sure I've tried his patience, over the six years I've been working on this boat, calling with my anxious and clueless questions. Maybe he finally snapped. That said, I'm pretty sure that I am right, and the diagram is wrong.

Once this boat is launched, I'm going to have a big pile of bug reports for CLC. But I can't launch until I figure out how to do carry out the metallurgy operations required to get the gudgeons and pintles bent into shape.

Nuts and bolts: Finally, the assortment of nuts and bolts provided by CLC, needed to attach the gudgeons, pintles and cleat, and to attach the rudder to the casing, are not quite right. I had to go to a hardware store and get what I needed.

July 16, 2025: I have put the rudder work on hold. My pleas to CLC have resulted in feedback, from support people, and on the forum. It looks like the gudgeons don't need to conform all that closely to the hull. But I still think I'm going to need help, so I've contacted a handyman who has metalworking experience. This is cheating, I think, but I'm now resorting to any means necessary to get this boat launched this month.

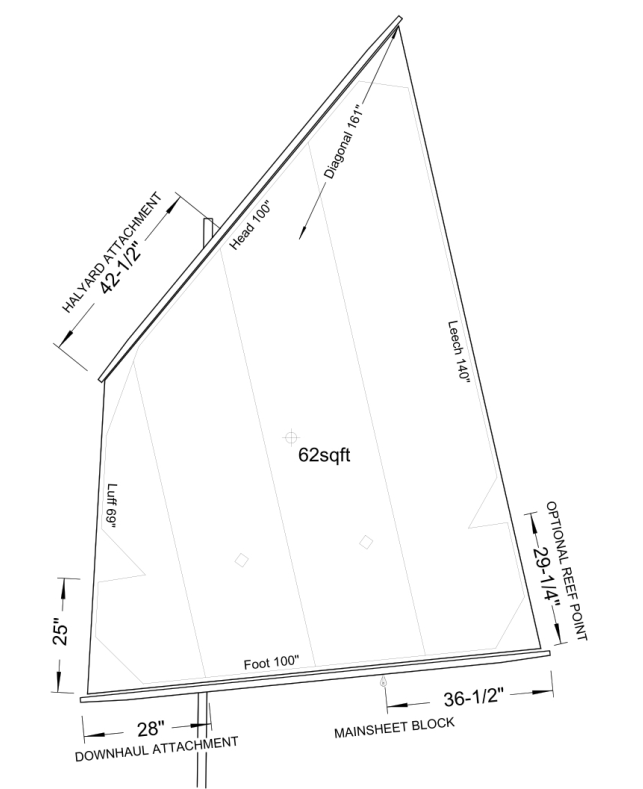

Meanwhile, I've moved on to the spars —: the mast, boom, and

yard. I chose the lug rig, which looks like this:

The mast holds everything up. The sail is stretched between the boom (bottom) and yard (diagonal piece on the top of the sail).

The sail is stretched on the yard and boom, and the mast holds everything up using lines, which are thin pieces of nylon rope. I have to drill holes in the spars for all of this to work.

The mast has a cross-section of 2", and it needs a 1" hole at the

top. Creating this hole is somewhat terrifying. That is a big

hole, and my puny drill cannot accommodate a 1" drill bit. But there

is another device called a hole saw that should do the job. This is

basically a drill bit with a circle of metal, 1" in diameter, with a

sawtooth edge. Look at this nightmare.

I did a dry run on some scrap wood, and it worked fine. But I

thought I destroyed the hole saw. This is what it looked like

afterward.

A plug of wood filled the space between the drill bit and the

saw. Of course, this sent me to google to find out what to do. I

learned that I could have bought another tool, a special

extractor built just for this situation. Fortunately there is

another solution. The hole saw has cutouts in the side, so that you

can poke around with a screwdriver to loosen the plug. This worked.

While I was doing all this, my family was enjoying the beautiful

lake and weather. (This is a cheap shot, they are all working.)

Next, I got ready to drill the mast. You can't just drill from one

side to the other. That promises to splinter the exit side. So the

thing to do is to drill halfway down, flip the mast over, and then

drill the other side. And in order to do this, the starting points on

the two sides of the mast have to be lined up accurately. I approached

this very carefully. I duct-taped a bracket to the side of the

mast, and measured 1" down, and then 1/2" across, and then repeated

that on the other side. And then I removed the bracket, and measured

a few more times, just to be sure. This black dot is the result

of all that work.

Now that I knew where to drill, I wanted to make sure that I

drilled straight. On each side I drilled a small starter hole. Then

a somewhat larger starter hole. Then, I got out the hole saw and

drilled the big hole, alternating between the two sides. For each

of these drilling operations, Audrey helped me make sure that the

drill was perpendicular to the surface of the mast (with eye

protection, of course).

It all worked out. Look at that hole. Just look at it.

And look at that plug. Just perfect.

Notice that the two halves of the plug are aligned. I really did get the two entry points lined up, and managed to drill straight through.

Then, using a conventional drill bit, I put in the necessary holes

in the boom and yard.

92

July 20, 2025: The brackets are still on hold, although

Jeffrey made some progress bending one of them into a better

shape. Meanwhile, I started rigging the sail. I laid out the sail,

boom and yard.

I spent some time making sure that I knew how to follow the

directions, and tie the knots correctly. Here is the boom.

Working on the yard.

Done.

July 21, 2025: Back to the brackets. For once, CLC support and the CLC forums weren't useful. I don't know how other boatbuilders have gotten these brackets to fit, but vises, pliers and wrenches didn't work for me. Both ChatGPT and Reddit's /r/metalworking suggested blowtorches. So I contacted the handyman I mentioned, and he showed up with a truck full of metalworking tools. He managed to get the work done, but kept muttering about how he really wished he were in his workshop where there is no wind to prevent the blowtorch from lighting, and where he had his anvil.

So that's where we are, CLC. A blowtorch and anvil, as well as assorted hammmers and tongs are needed (by me, at least) to finish this boat. Come on, CLC, you have a problem with these brackets. Do better.

Readers, meet Denis Grover, a master of

working with all kinds of materials involved in building useful

objects.

Here is the blowtorch, mounted to a vise that is permanently

attached to Denis's truck.

Here is Denis's jerry-rigged anvil.

After some trial and error, in which the collar was deformed, Denis

hit on the idea of using the handle of this special wrench which has

a conical shape, sort of like the thing used to size rings in a

jewelry store. This was useful for expanding the collar once it had

been squeezed too much, and also for holding and maintaining the

bracket as it was being bent.

An early attempt to fix the bracket.

Look at this, CLC. This is what is necessary to get these brackets

to fit.

July 23, 2025: This is the third year in a row when I promised myself and my family: The boat will launch this year. But in each of the previous two years, the realization that it wouldn't came slowly. So by now, that feeling is familiar, and I was starting to feel that way because of the brackets. I know that feeling well from working on software: my program is just about complete, and then I run into a little bug, or minor inconsistency, and the more I think about it, the worse it gets, revealing a deep problem, and then I think "how did this ever work at all?!", and then I find myself with another few weeks to go, because the problem is so pervasive.

But no, Denis did a great job on the brackets, and they fit

well. So the next task is to attach the gudgeons to the hull, and

the pintles to the rudder. Each pair has to line up perfectly

straight, and they have to fit together so that both pintles fit

into the matching collars completely, and the rudder can

rotate. Here it is mocked up with the brackets attached using duct

tape.

I started by taping the gudgeons into place, and making sure they

are aligned, by passing a dowel through the collars, and then

marking where to drill to attach them permanently.

And here they are, each one half attached. This will give me literal

wiggle room, to line up accurately with the pintles on the rudder.

Figuring out exactly where to attach the pintles.

The next thing to do is to drill straight through the rudder casing. These holes have to go through a couple of inches of solid wood (all the layers of the rudder casing), so I will need to be very careful to drill exactly orthogonally to the surface.

Finally, in addition to the basement and kitchen being taken over,

I need a lot of space to complete the rigging of the sail. So I

vacated the upper garage (alert longtime readers will recall that

this house has two garages), and laid out the sail there.

Rigging the sail is actually quite simple. This realization was hard-earned. The Skerry manual provides only the sketchiest information on how to rig the sail, and some key diagrams are missing. So the support folks at CLC sent me the manual for a different boat (the Passagemaker) which has good instructions for setting up the lug rig that I have. So now I have two manuals, each with its own internal inconsistencies. I identified the different rigging tasks, studied each in detail, in each manual, and emerged with a long list of questions.

After a long discussion with Andrew (who said he has built 10 (!) CLC boats:

I'm back in Somerville for a few days. When I return, I will finish the rudder, finish rigging the sail, apply the decal with the boat's name, and launch the boat.

July 27, 2025: Back in Maine. I finished up the rudder

today! I started by double-checking the positions of the pintles on

the rudder, making sure that everything still fit together.

Then I needed to drill holes through the rudder casing. My vise

setup in the basement has always been rickety. The folding table is

flimsy, and the edge doesn't allow for the vise to be attached

securely, or parallel to the floor. Audrey had a good idea for a

fix: Move the vise to an island in the kitchen and clamp the rudder

casing. Then put the drill upside down, resting on the surface and

arrange it so that it is perpendicular to the rudder casing. By

resting the vise on the surface, that removes one direction in which

things can go wrong. I also used these right angle brackets to guide

the drill. (These brackets keep coming in handy.)

This worked! The drill came out very close to the marked spot on

the other side of the rudder casing, and here we are with pintle

half attached.

And with both half attached. The rudder fits well and rotates.

The second set of pintle holes worked out okay too. These were more

of a concern, because this time the pintle is in place, so if I

don't drill correctly, I would be drilling through solid metal of

the pintle (or, at least, attempting to). But it all worked out, and

the rudder casing attaches to the boat, rotates, and detaches. Yay.

In order to finish the rudder completely, I need to attach the rudder deployment line cleat to the top of the rudder. Alert readers will recall that we have discussed this part, and the error in the manual advising me to install the cleat upside down. Well, I've lost the cleat. Fortunately, Julia is in Portland, and fortunately, there is a West Marine in Portland, and in a final piece of good luck, they have the cleat that I need. So Julia should be bringing back that essential piece tonight.

With the rudder work done, it was time to start applying the decal. Audrey, who has been training herself to be a graphic designer, designed the logo. She found a font matching the one used on Talking Points Memo, carefully worked out the size of the graphic, and the kerning, and sent it off to be turned into a decal.

We thought we were getting one big decal that we could just

apply. We thought this would require some care to get things

lined up right, but would be pretty simple — peel and

apply.

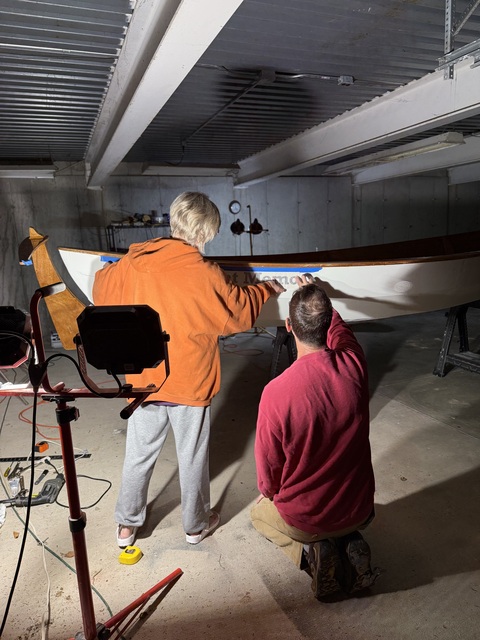

But no. The kerning was all for nought, because the stupid decal-creating place sent us the precisely kerned letters (see photo above) as individual decals! Yes, the idea is to peel off each letter and apply it to the boat. This is madness. Who thought this was a good idea? Audrey may be writing them a letter (IYKYK).

We briefly considered just using the initials, FPM. But Audrey

wanted to see it through, so she is applying the letters, very

carefully, one at a time.