The interior of the boat is done once I install some wood pieces to support the mast. After that, I need to work on the mast, spars (the boom and yard — other long sticks of wood that support the sail), rudder, daggerboard.

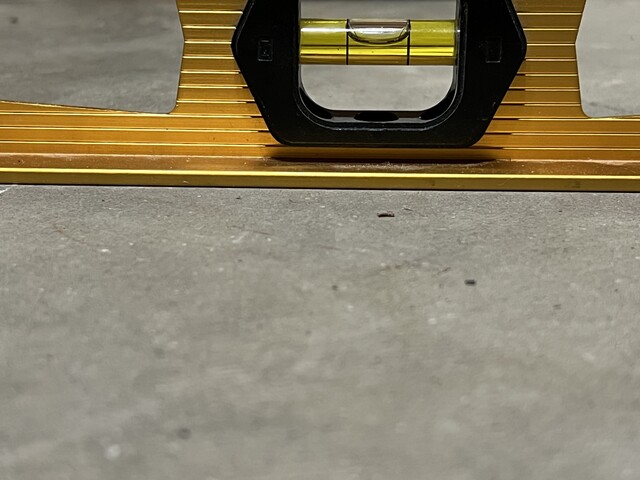

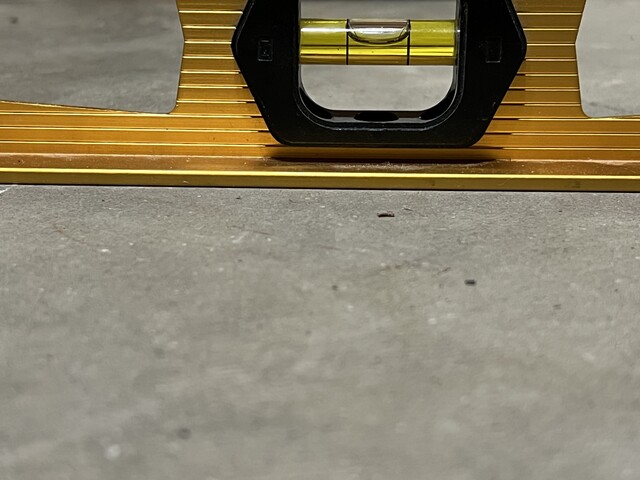

To begin, I wanted to ensure that the mast will actually be at

right angles to the bottom panel and seat. So I used a level to make

sure that the floor itself is level, and then I checked the horizontal

surfaces of the boat, which is resting on the floor.

Looks good.

Next, I temporarily installed some braces to make sure that the mast is at right angles to the seat.

No, this is not the entire mast. No, the mast hasn't already

snapped. Like the rails, the mast is shipped in two pieces, which will

have

to be epoxied together.

That was a dry run for later. For now, all that I needed to do was to install the mast partner, a reinforcement under the front seat, around the hole through which the mast will be inserted.

I turned the boat upside down,

Installed some lights,

And installed the mast partner.

July 7, 2023: To finish up the seats (yes, they are installed, but not quite done), I need to apply fillets. Alert readers already know what a fillet is, but for the rest of you, it's epoxy mixed with wood flour (to an organic — not Skippy — peanut butter consistency), applied at the seam where two pieces of wood come together. Installing the seats created more such seams, so more fillets are needed.

The boat is upside down, so I decided to apply the fillets to the

underside of the seats. This requires me to work, and crawl around, on

my knees, under the boat, for hours. This is not really the sort of

thing you want to do at my age. Although, I did get an occasional

break, to mix more organic peanut butter consistency epoxy.

(I'm not sure why the boat looks so tilted and about to fall over, in that first picture. It's resting quite stably on the sawhorses.)

When the boat is flipped rightside up, I'll do the fillets for the seat tops, and then the seats are really done. I'm also assembling the mast step, and that should be pretty easy to install.

And then after that, I need to assemble the mast, boom, rudder, tiller, and attach these to the boat. So the end is in sight. I'm also starting to think ahead to other problems:

July 12, 2023: It was all going so well, and then it wasn't.

I am indeed missing a part of the rudder. Nicky agreed to send it, and

I managed to typo the zip code, so that will cause a delay. And then

after I applied the latest coat of epoxy to the mast step, I set it

down to dry on the canvas dropcloth. For a previous coat, I set the

mast step to dry on a thin plastic tarp, and that got stuck to the mast

step. So I cleverly avoided the plastic, and put the mast step on the

dropcloth, which binds much more tightly. And in attempting to

remove the canvas, I broke one of the mast step sides.

So I wrote to Nicky again, to ask about buying another set of mast step pieces. I could buy some wood, and cut the pieces myself, but knowing myself, that's a major and time-consuming project, and I don't have the tools to cut out the square.

Meanwhile, I epoxied the boom and yard. That's a small I-beam that

the pieces are clamped to. The guy who built the house used material

like that in a few places, so I just happened to have that I-beam

sitting around.

I'm not assembling the mast yet. I'll need that short piece of mast to fit mast step 2.0.

July 13, 2023: While waiting for the replacement mast step to arrive, I

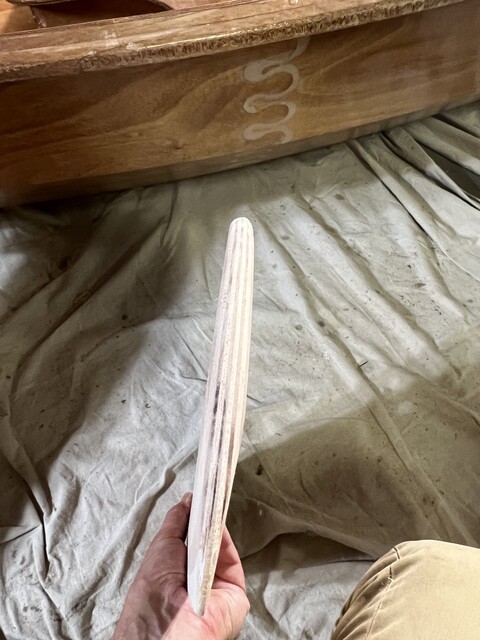

worked on the daggerboard. It's a 1/2" thick piece of plywood.

Shipped from CLC, the daggerboard is of uniform thickness, i.e., the cross section is a rectangle. To work as a daggerboard, minimizing drag, it needs to be shaped like an airfoil, an elongated teardrop. While the CLC forums are often helpful and reassuring, sometimes it's like being at a bar, where everyone is friendly and welcoming, but you realize, oh, these are PhD mathematicians, and you are incapable of understanding much of what they are saying. So the advice on how to shape the daggerboard was both thorough and useless to me. It involved tools I've never seen before, operated with a very high level of skill. For example, there's this two-handled planing contraption, called a "spokeshave". And to use it properly, you need to move it in a perfectly straight line across the length of the daggerboard, at just the right position, at just the right angle, many times, with different positions and angles each time.

Knowing my limitations, I looked for a simpler approach. Most people seem to do what is documented poorly in the Skerry manual: approximate the airfoil shape by rounding the leading edge, and tapering the trailing edge. I talked to Nicky some more, she sent me useful diagrams from the manual for a different boat, and she also provided advice on tools. (Belt sander: too aggressive, which is just as well since I don't have one.)

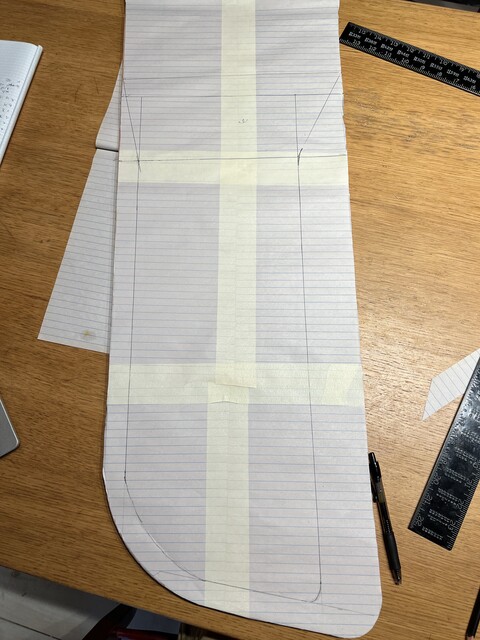

Putting all my information together, I started by creating a

template showing me where to operate on each side of the daggerboard,

and making sure I would treat the two sides symmetrically.

This was time-consuming, and turned out to be completely useless.

First I used a router with a 1/4" roundover bit to round the

leading and bottom edges.

To taper the trailing edge, I first marked the middle layer of

plywood, to avoid sanding too much on either side.

My choice was to do the tapering using the sander or the plane. I thought it would be too difficult to make the surface completely level where I was tapering, so I used the plane. As before, I found the plane fiddly and I had to keep stopping to blow out and otherwise remove accumulated wood shavings. Scenes from my afternoon:

Getting used to the plane again.

Approaching the midline on one side.

One nice thing about plywood is that the different layers look

different, and that provides useful visual feedback on what's been

done, and where work is still needed.

You can't really see that shaping from this view.

So here are the edges, trailing:

And leading:

No epoxy today!

July 14, 2023: And the rudder is done:

July 16, 2023: I'm still waiting for the new mast step to

arrive (should be tomorrow). So I decided to make progress on the boom

and yard. Those are identical 10' lengths of wood, 1 1/2" square. I

need to taper each one, 20" from each end, to a 1" square. One face,

which will be the top side, is

supposed to be left alone, so I'll take 1/4" off each side, and 1/2"

off the bottom. I marked these dimensions on one end and drew lines to

guide my work. (This is midway through tapering the bottom.)

The block plane is my new enemy. I need to do a lot more planing

here, compared to the daggerboard and rudder. I spend a lot of

time adjusting the blade height (too low and nothing gets removed, too

much and I gouge the wood and get stuck); clearing out shavings; and

just figuring out how to apply this taper. I managed to get it done,

and the taper looks pretty uniform, but it wasn't pretty. So after

getting this part done, I took a break and reviewed youtube

videos. This revealed one weird trick that made a lot of

difference: orient the plane at an angle.

After my break, I tried that, and it helped a lot. But also, I just seemed to need much less time to adjust the blade height correctly. I think probably that the sides of the wood presented a different grain compared to the bottom. I'll see how it goes when I work on the other three (ugh!) tapers.

My mental model of a plane was that it removes a very thin, but uniformly thick strip of wood. I formed the taper by planing more where more wood needed to be removed, less at the other end. But there is a lot of variability. The strip that you remove can vary in thickness depending, I guess, on pressure, the angle with which pressure is applied, and small changes in the angle between the blade and the wood. It can be slightly tilted at one edge of the wood. And because the wood is wider than the plane, another variable is the depth across the wood. Anyway, of the four boom and yard ends I need to taper, one is completed.

July 24, 2023: Julia is visiting for a week, and I'm sad to say that the boat will not be done while she is here. She guilted me into agreeing to get the boat in the water during her visit, and I really tried. I spent a lot of time working on the boat in May and June, a much more concentrated effort than in the previous four (!) years. But it just won't happen. I still think I can finish the boat this summer, but it will be after she leaves.

Just before Julia arrived, Hannah and I went to dinner in

Portland. On the way back to the car, this happened.

After I finished planing last time, I thought that it would be a good idea to sharpen the blade. So I looked at videos, got out my sharpening tool, and destroyed the blade. After that, the plane didn't work at all.

I went to Rockler, had a long therapy session with them, and left

poorer, but with a new plane and sharpening tools.

They confirmed what I heard in one of the videos I saw, the bottom-of-the-line Stanley plane that I had been using is indeed "junk". The guy at Rockler brought out a new plane, also by Stanley, but about triple the cost. It took him about 5 minutes to get it working. He then instructed me to go home, take it apart, clean everything with turpentine, put it back together, and it would be fine, just fine.

This filled me with trepidation. If he took five minutes to get the

plane working right out of the box, what kind of journey was I in

for, taking the plane apart and putting it back together? But it

was, in fact, just fine. I took it apart, put it back together, and

it just worked. Behold:

With my new favorite tool, I quickly finished planing the spars.

I now have a deeper understanding of what happened. My junky bottom-of-the-line Stanley plane was gaslighting me. I would loosen the top thingie, turn the screw a couple of full turns, which should cause the blade to poke out a lot more. Nothing, the plane still didn't work. Or sometimes I would tighten the screw just slightly, and all of a sudden it started working. Then it would stop working. It kept clogging.