I now need to install all the structures that go inside the boat, the centerboard trunk, and three seats: bow, stern, middle.

I am getting cautiously optimistic that I will in fact get the boat in the lake this summer. After all that work on the frames, and the seats, it seems like everything fits. The next steps are to install the centerboard trunk, epoxy and install the seats, and apply more fillets around these installed pieces. And then it seems like smooth sailing (hah! see what I did there?), in that the remaining steps seem to involve skills that I have not mastered, but have at least applied before.

But in order for the centerboard to actually reach the water, there need to be slots in the middle seat (which covers the trunk), and in the bottom of the boat. Yes, I need to cut a slot in the bottom of the boat. This, I hope, is the last terrifying and new thing that I need to do. (I think that the slot in the middle seat will be easier and less terrifying.)

I have been talking to my network of advisers about how to do this — CLC support, the CLC forum, Mark, and the guys at Rockler woodworking. Here's my plan:

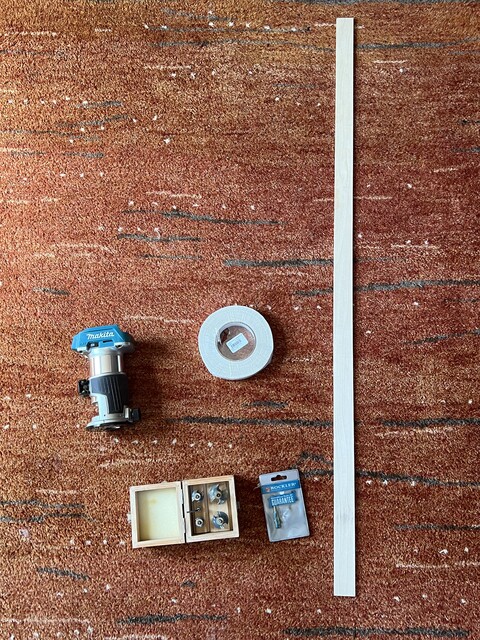

Here are my new acquisitions:

Counter-clockwise from the right:

I'm going to Maine later today to finish the fillets, and drill the slots.

June 1, 2023: It's a beautiful, summery day, actually getting

hot. Fortunately, my work area is cooler.

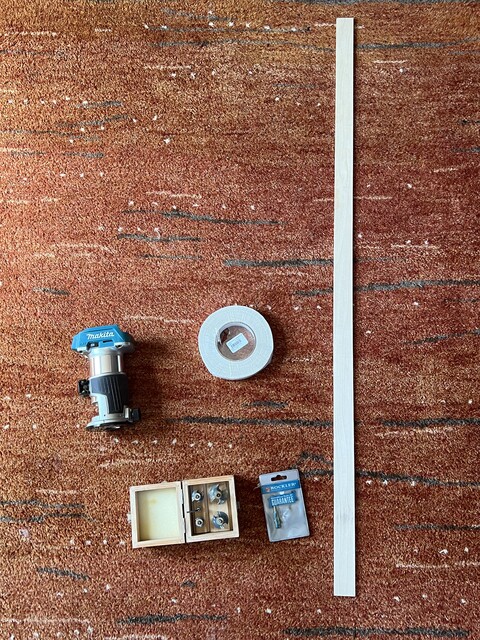

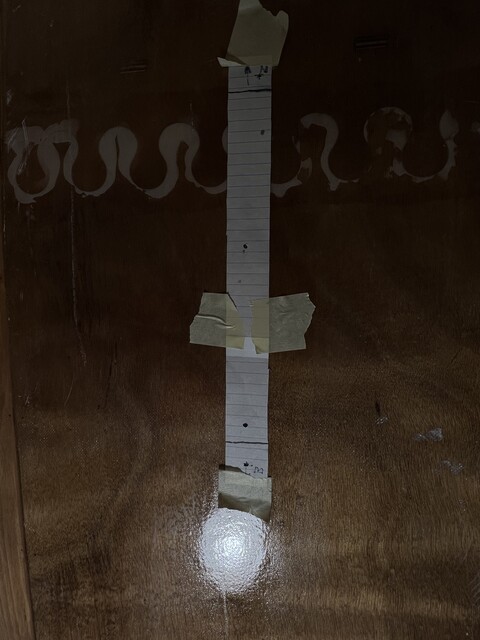

Easy stuff today. I drilled a couple more pilot holes for the

centerboard trunk, and then measured things and created a

template. I'll use this template on the bottom of the boat to figure

out where to cut the slot.

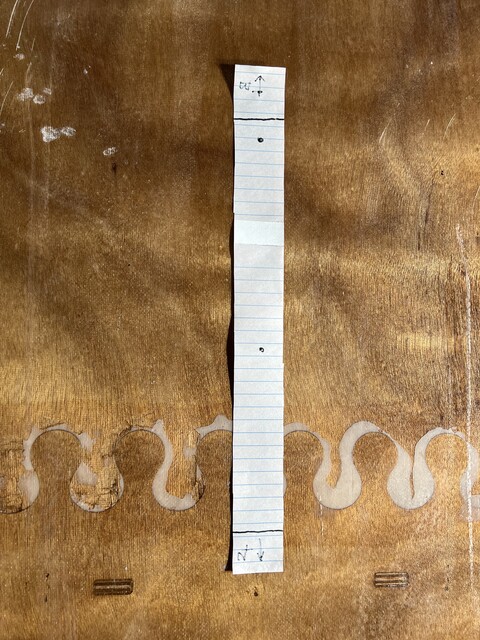

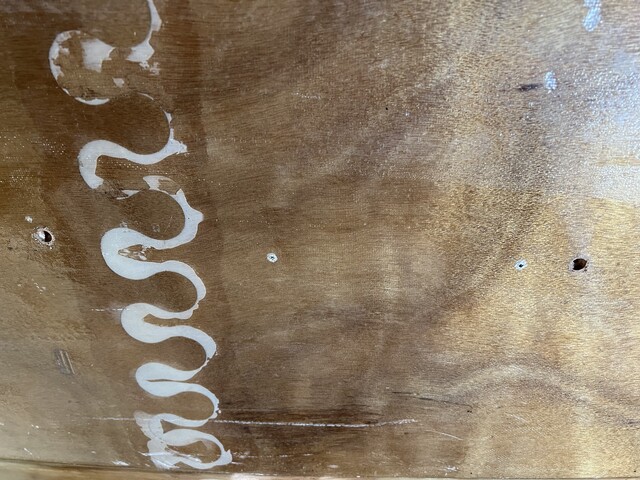

I'm seeing lots of scuff marks and dings on the exterior surface, so I'll

eventually have to do more sanding and epoxy to fix those.

I checked the fit of the seats one more time, and did a little sanding

to improve the fit.

Then I sanded the tops of the seats.

And applied the first coat of epoxy.

I also talked to CLC support again, to obsess over the installation of the centerboard trunk, the maneuver that involves cutting a slot in the boat. I finally stumped them. Nicky had to go consult with other sages there and get back to me. And the new procedure is a little different than what's in the manual. I need to epoxy and screw in the trunk, and then cut the slot, using the trunk as a guide.

Now I think that means that I have the wrong router bit. Instead of using those maple strips as a router guide, this new procedure would best be done using a router bit with a collar — a bearing at the end of the bit that would run along the interior of the trunk. Hmm. Have to think about this. This may warrant another conversation at Rockler, and possibly an exchange of one bit for another.

As for installation of the trunk: That's a two-person job, so I'll need to do that when Audrey is here. Once the trunk is glued in place, I'll need to work put in the screws (through the frame, and then through the bottom panel, working below the boat). Audrey will need to hold the trunk securely while I'm putting in the screws.

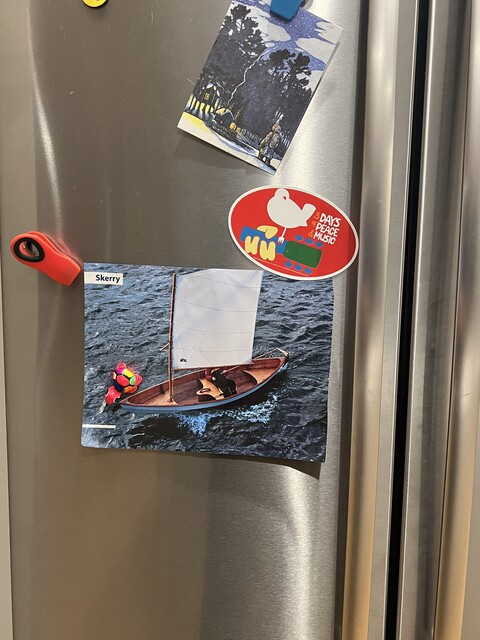

June 7, 2023: I hear that people have these things called

"vision boards", collections of pictures illustrating personal

goals. I realized that I have a vision board. It's a photo of

the boat I'm building, on my refrigerator.

I installed the centerboard trunk today, with Audrey's help. We

spent some time talking through the steps, and she had me consider

trimming the trunk some more so that it would fit better, avoiding the

need for shims. I decided to stick with the original plan, because a

change would invalidate the measurements I have taken, and the holes

that I have drilled would be in the wrong place. So with that decided,

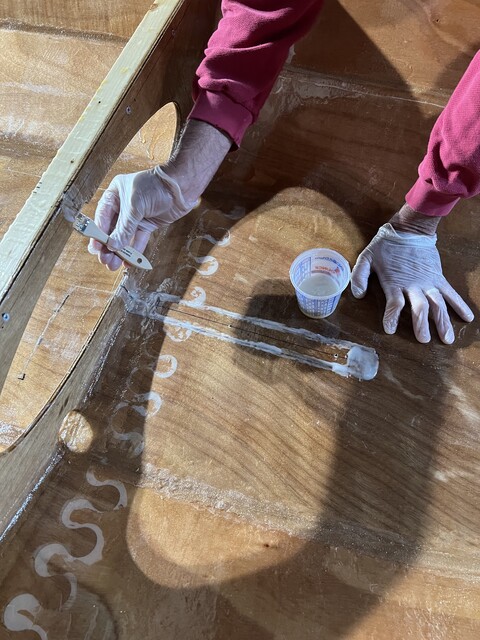

I laid out everything that I would need, and mixed the epoxy. First, I

applied the epoxy to the bottom panel and frames, and to the trunk.

And then I placed the trunk in the boat, with the shims, and put in

the screws through the frame and shims, and into the trunk. Then it

was time to raise the boat off the floor to get ready for the screws

through the bottom panel.

I lined up the template I had made last week.

And drilled the holes for the screws holding in the trunk.

And it's done.

June 8, 2023: Today I did the scary part, I cut a slot in the bottom of the boat.

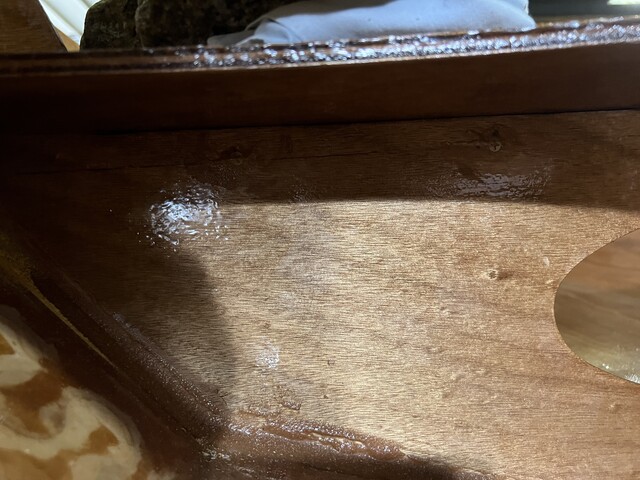

I started with something easy, applying the last coat of epoxy to the seat tops.

Then Audrey and I put the boat back on the floor, for the major surgery.

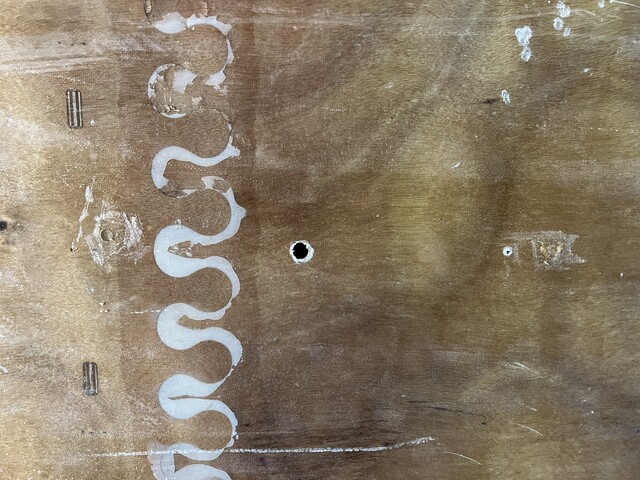

I have this massive, 1/2" drill bit, for putting a hole in the

bottom of the boat, to accommodate the router bit. (Well, it's massive

in my vast experience with drill bits.)

I tried a test hole in a piece of wood much thicker than the bottom

of the boat, and that went well.

So I drilled a hole in the boat itself, and that went well.

Audrey helped me measure the width of the centerboard trunk, to

make sure that I drilled a slot of the correct width.

Here are today's implements of destruction:

I realized that I had the WRONG drill bit. I did go back to Rockler, to get a router bit with a bearing to be guided by the trunk itself. What I intended to get was a bit with the bearing at the far end. I got one with the bearing at the near end. So back to my original plan, using wood strips taped to the boat as a guide.

I started a bit unevenly, as I figured out how to adjust the

router's bit depth properly. Marked had warned me that I needed to

be conservative, and route one layer after another. He wasn't

kidding!

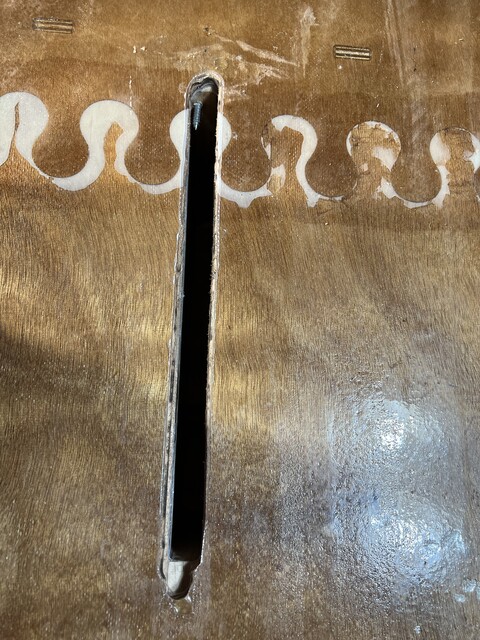

I finally got the slot cut.

There are now two problems. First, I cut the slot too long, (on the left side of the photo). I'll have to fill that in somehow. More seriously, I put in a too-long screw through the frame. Not sure what I was thinking. I'll need to back out that screw and put in a shorter one. I wonder how easy that will be, what with all the epoxy on the frame, and between the frame and the trunk.

June 9, 2023: Laszlo (wise man on the CLC forums) says these are easy to fix. For the first problem, fill in with epoxy and wood flour, and cover with fiberglass. The other problem sounds more difficult: heat up the screw if necessary, and once its out, plug the hole with a dowel covered in epoxy, or inject epoxy/wood flour. I'm going to try removing the screw now.

Twenty minutes later: Okay, this isn't good. I used a heat gun to remove the epoxy on top of the screw, and discovered that the screw is stripped. So I have a screw that must be removed, that is stripped, and cemented into place with epoxy. And it's a wood screw, countersunk, so the top of the screw is flat, and flush with the surface. Researching ...

June 16, 2023: I didn't work on the boat this week, because there

is too much going on getting ready for the summer.

My major responsibility this week, was to pick up Hannah's cat,

Eloise, who, along with Hannah, will be in Maine for the summer. You

remember Eloise.

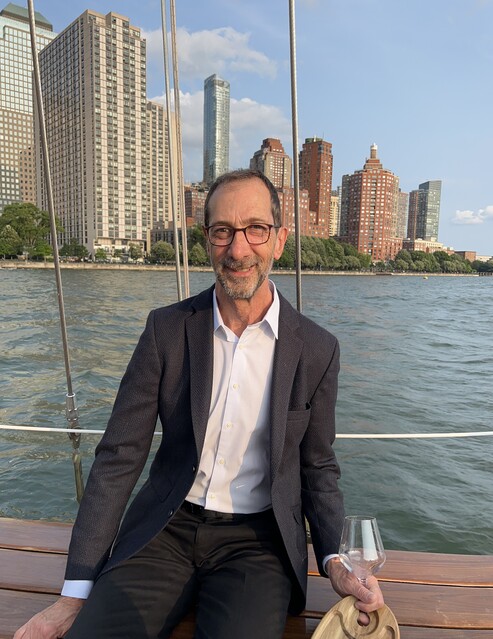

I drove to Brooklyn on Thursday. Hannah had already committed to a work-ish event. The Louis Jadot winery (is that the right word?) was sponsoring a cruise for press people. Five courses (apps really), and one of their wines paired with each. Hannah got an invitation for me because I can claim, with some justification, to be a press person. Yes. During the pandemic, all four of us were living together, in Somerville, and one of our entertainments was binge-watching Love Island. Hannah and I have continued the tradition, MST3K style — wise-cracking by text while watching the very silly goings-on. We somehow decided that I should try to be a Love Island opinion writer, and I actually managed to get an article published by Bustle UK. That article was almost entirely rewritten by the editor. Just about none of my original writing is present. Still, my name is on it, so I count as a press person.

The cruise was on this 70 ft. sailboat, which is why I mention the

event here at all. Here we are, Hannah dressing normally, me dressing

up.

The cruise departed from a pier near the World Trade Center.

It went past Ellis Island, and the Statue of Liberty.

This is a real sailboat.

A really nice evening, with perfect weather. And clear air. The cruise was originally scheduled a week earlier, but that was when the smoke from the Canadian forest fires rendered the New York air the worst in world history.

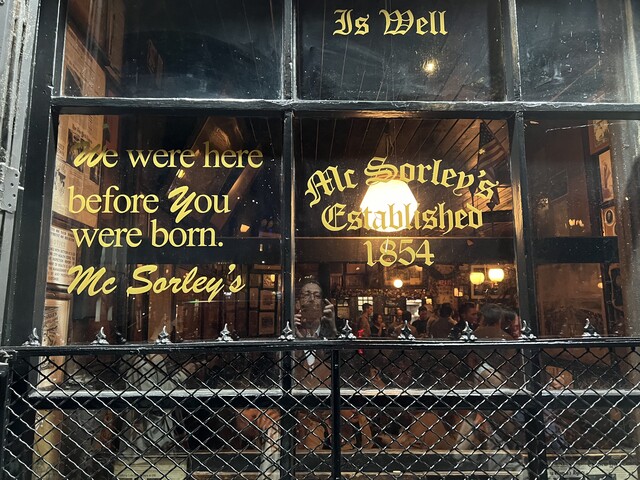

After the cruise, we went to one of my old haunts. In 1978, I lived

at 17 E. 7 St. in New York. It was a pretty disgusting studio

apartment which I shared with a large extended family of

cockroaches. The rent was $185/month. According to Zillow photos, the

building is much nicer now, and the rent is $3400/month.

We also visited McSorley's, right next door, which, unlike my old

building, does not seem to have changed in any way in the

last 45 years.

June 21, 2023: We are in Maine for the summer: Audrey, Hannah, me, and the cats, Cat5, Moo, and Eloise. We drove up in two cars, Hannah and Eloise were in one car. Eloise travels easily, she just zones out in her carrier for the entire trip. Audrey, me, Cat5 and Moo were in the other. Cat5 and Moo hate traveling, and they make their displeasure known by emitting from all orifices (including lots of meowing). It's disgusting. Sometimes it really is a two-person job to deal with their protests. So we have taken to dosing them with a sedative (vet-prescribed) before traveling. But toward the end of our trip from Somerville to Acton, no matter how drugged he is, Cat5 always knows when we are on Berry Rd., and throws up there. It's a short road, maybe 1/2 mile long. He just knows.

Previously, on Area Man Struggles to Expand Horizons: That too-long screw was poking into the centerboard slot. I've been asking everyone about how to fix this, the CLC forums, Mark, the guys at Rockler, people at various hardware stores. I investigated but decided not to try a screw extractor. From my research, screw extractors are iffy, they work best on shorter screws, and no testing that I saw involved screws glued into place with epoxy.

One of my consultants was a young woman who works at Ace Hardware in Porter Square. She seemed to know what she was talking about, and confirmed my suspicions about screw extractors. She recommended trying a thin, tapered, triangular file, and just cutting off the screw. And if that didn't work, my plan was to dig out some of the wood on the frame, around the screw head, and try the vise grip.

I tried the file, and it did seem to make progress. Here is the

file, with some metal shavings from the screw, sticking to the file.

I tried wiggling the screw with the tip of the file. That did not

go so well, the tip of the file snapped right off. But enough of the

file remained to reach the screw and work through it.

Progress!

More progress!

Success!

I filed down the remaining nub, and this crisis is over.

I also applied another coat of epoxy to the seats, and escorted

this visitor outside.

June 28, 2023: It's been a gloomy few days at the lake. Oh, and Audrey has COVID again! We suspect our recent visit to the Plough and Stars for a Handymen show. She's a bit tired, and has been congested and sneezing, but is otherwise fine. I tested negative yesterday, and will check again tomorrow.

I finally finished the centerboard slot.

It looks to me like the

slot is angled very slightly to the left of the center line.

This is something I'm going to have to live with. Also, my routing of the slot was a bit sloppy, so it is possible that it's only the slot that's off, not the centerboard trunk itself.

It is time to finally install the seats. I'm starting with the

middle seat, to finish up everything related to the centerboard

trunk. So I need to glue the seat in place, and then cut a slot in

it to accommodate the centerboard. Just last month, I made sure that the

seats would fit the frames, so the seat should just fit, right? Right?

The seats don't fit. After making sure that the seats fit, I applied fillets to all the panel/panel and panel/frame seams. And I epoxied the seats, including the edges. So everything is very slightly different from the way it was when I made sure that the seats fit. Still, how bad could it be? I've had worse problems building the boat, but this one is irritating. This problem is like solving a Rubik's Cube, and it's solved except that two of the cubies need to be swapped. So close, and yet so many steps to fix the problem.

The middle seat mostly fits.

But it doesn't sit flat against the frame.

After a lot of close visual inspection, wiggling the board to see

where it was stuck, and sanding,

I am not too worried about the sanding removing the protective layers of epoxy. The sanding was all at the edges, in places where there will be lots of epoxy applied: to glue the seat into place, and then fillets to protect these new seams.

I got everything to fit.

Finally, I applied epoxy to the underside of the seat,

And to the frame and centerboard trunk,

And fit the seat onto the frame, weighing it down as recommended

by the manual.

That looks pretty secure. No visible gaps, and epoxy is squeezed

out (which I cleaned up).

June 29, 2023: I cut the centerboard slot in the middle seat. As before, start with a hole.

I finally got the right router bit, the one I should have had when cutting the

slot in the bottom of the boat. Crucially, the bearing is at the end

of the bit, not on the

other side of the blade.

Look at that slot.

Just look at it.

June 30, 2023: The sun has finally returned, so we are once again enjoying the lake. Here are some indoor and outdoor scenes.

Eloise does not get along with the other cats, Cat5 and Moo. She has found a

place to be alone, in the linen closet.

This dude has been sharing my workspace for a few days. I finally escorted him

outside.

Correction: The spider is not a dude. It is a dudette. I know this because experts on Reddit's r/spiders said that this is a nursery web spider, a pregnant one.

Here is the house during yesterday's sunset.

Hannah is driving the boat more than me this summer.

During tonight's sunset cruise, we saw a group of loons. We love loons.

Okay, back to work. I installed the bow seat today. Unlike what happened with the middle seat, the bow seat still fit pretty well, just a little sanding was needed.

For the middle seat, I mixed a lot of epoxy,

way too much, and it started turning into a hockey puck bomb again, heating up and solidifying.

To avoid this problem today, I mixed two small batches. Mixing epoxy with enough silica powder takes

a long time, maybe 15 minutes. And then, once it's mixed, I wanted to work very fast, to avoid

more hockey puck bombs. So I quickly applied epoxy to the seat, the frame, and put it together.

Still need to do fillets, where the seats meet the hull and

centerboard trunk, but the seats are done!