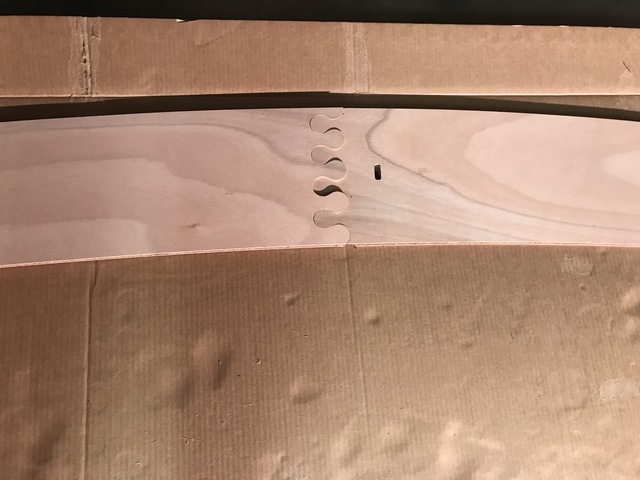

The boat only weights 100 lbs. when built, so it ships in a surprisingly compact package. But the assembled boat is 15 feet long, so of course they can't ship the panels of the boat as single pieces. Each of the seven panels (one bottom, three for each side) comes in two parts, that fit together via "puzzle joints", and all I have to do is glue them together.

How hard could it be?

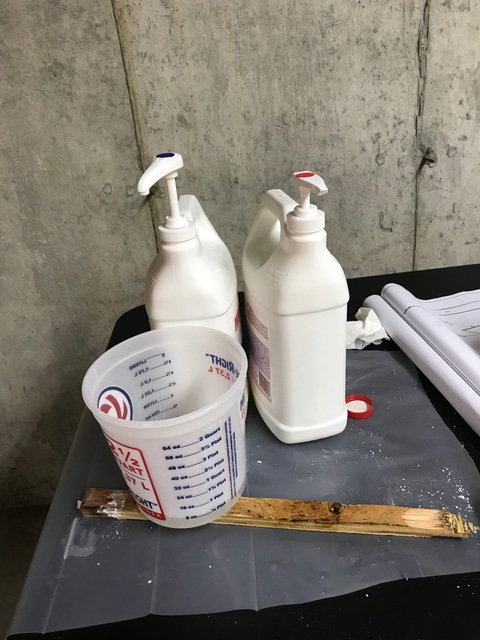

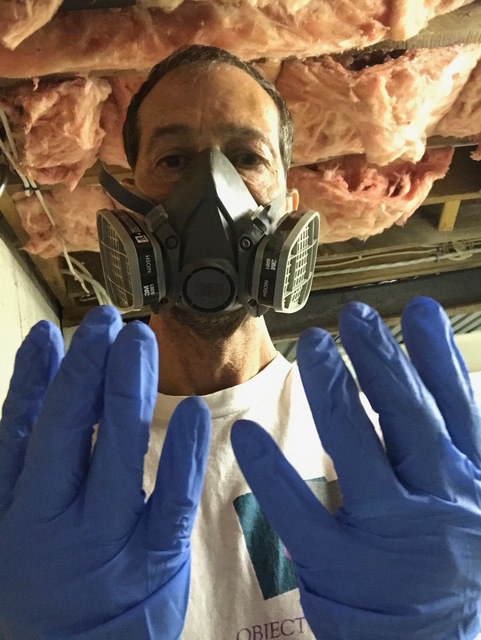

So now I see how hard it could be. The manual says to mix the epoxy resin and hardener, combined with a filling material, to "mustard consistency". So I measure things precisely, and then use my vast experience with mustard to gauge the amount of filler.

I dab it on to the surfaces of the bottom panel's puzzle joints, and put it together. That seemed to go well. So without waiting 24 hours for the epoxy to harden, and with the enthusiasm of a beginner on a new project, I mix a big batch of epoxy for the side panels.

I am getting comfortable with this now, and working on the side panels, when I begin to notice that: 1) The container of epoxy is getting hot. Uncomfortably hot. Painfully hot. 2) The epoxy is getting thicker. It is basically turning into a hockey puck. So I put this incipient hockey puck bomb outside and call CLC support. "Oh yeah, that happens ..." and he directed me to the fine print on the website where they say that it happens. Apparently, the reason you mix epoxy is that the resin and the hardener participate in an exothermic chemical reaction. And as it heats up, it accelerates the reaction. So basically, positive feedback. They obviously don't want that reaction happening while the epoxy is being bounced around UPS trucks. You can avoid this problem by mixing small batches, and by spreading out the epoxy in a tray. Neither of which I knew, but admittedly is mentioned in the fine print. (It would have been nice to include this in the manual!)

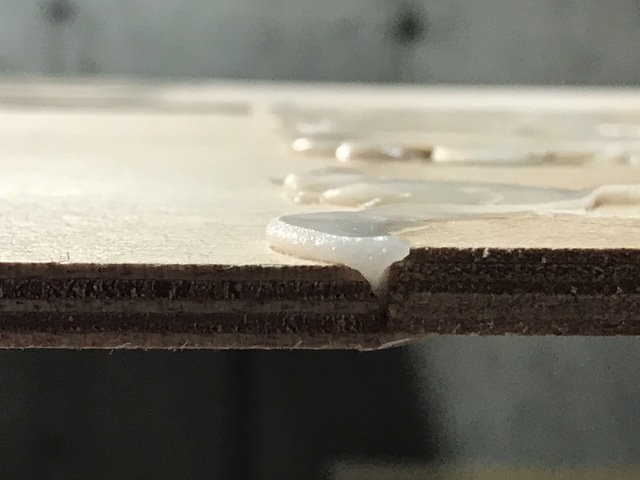

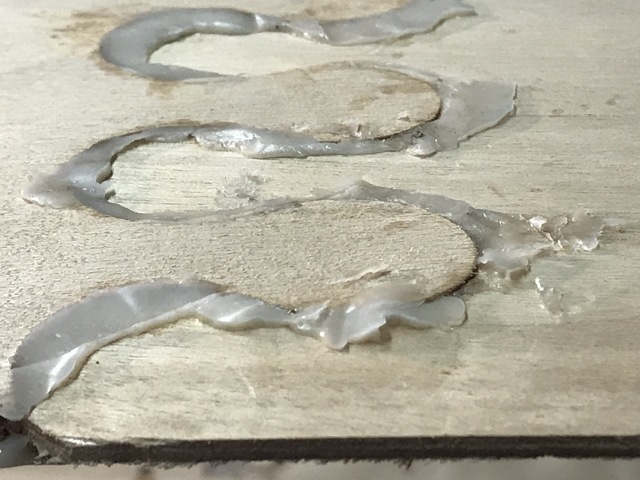

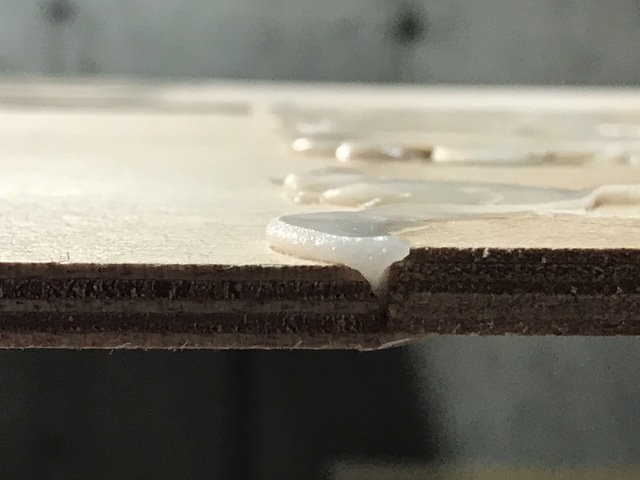

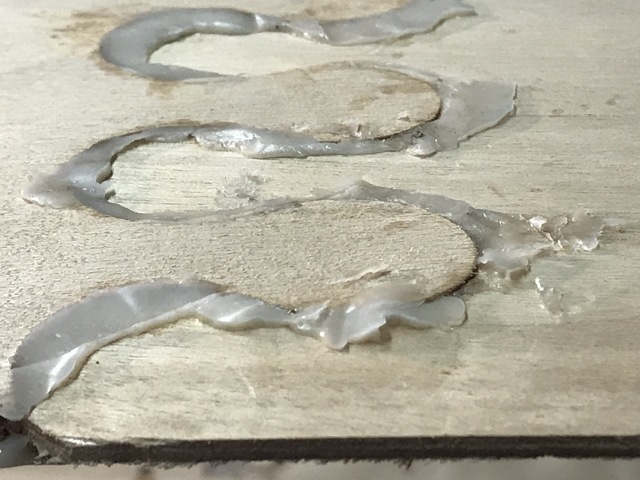

Because of this learning curve (and other things I missed), the

joints aren't so great. The epoxy was thicker than "mustard

consistency", I applied too much, epoxy squished out to the panels,

and in one case, I misaligned the panels.

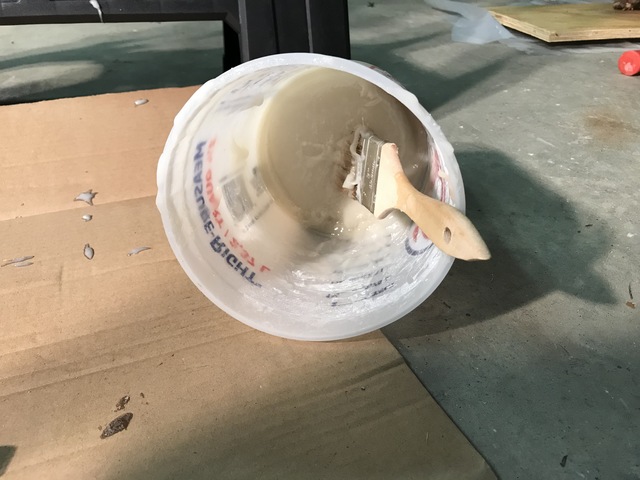

I worked out a strategy to fix the problems with the helpful guys

at CLC support. Sand it down, and use epoxy (without filler) to

create a smooth surface.

The joints are now sanded down and filled in with epoxy, so the

surfaces are all smooth. Not pretty though. So I'll be painting the

boat, not staining it.