I've been working on the exterior of the boat for a long time. A long time. My projects tend to be that way. A few examples:

There is still a little more work to do on the skeg, but

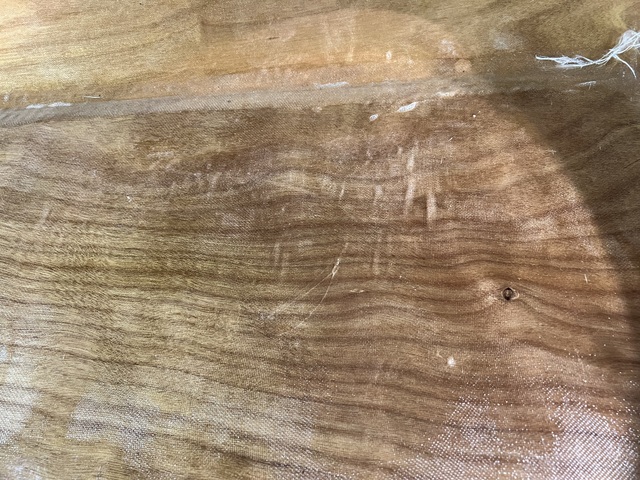

now it's time to work on the interior. What a depressing sight. Look

at this mess.

I guess there is some humidity in the basement. And having the boat upside down for months at a time probably helped trap moisture. That looks like mold to me. Also, look at how the frame (the thing with the hole in it, yes, the hole is supposed to be there), attaches to the hull. There are gaps. The epoxy is a mess.

I sanded the frames, which at least made the wood look less

moldy. Further treatment might be needed though.

I also sanded various random epoxy splotches and found remaining bits of wire to remove.

I'm going to check with the forums about the mold and cleaning up the epoxy, and then start on the interior fiberglass.

August 1, 2022: The advice (a couple of weeks ago) was to scrub the

affected wood with diluted bleach, and then let it dry in the sun. So

I did that. Note that this is the first photo showing the boat, and

the lake in which it will eventually float (let's hope).

Moving on.

The exterior of the bottom and first panels were covered with fiberglass and then a few layers of epoxy. I proceeded after great trepidation, but it went pretty well.

Now I have to do the same to the bottom and first panels on the interior of the boat. There are a few problems here.

First, the exterior of the boat's hull is convex. (Digression: In grad school, I happened to be around people who were getting the field of computational geometry started. And one of the first problems examined was computing the "convex hull" of a set of points — basically what you would get by stretching a rubber band around all the points. The problem is to compute the shape of that rubber band, which is a convex polygon. This is a very cute problem because it is definitely geometric, but the solution uses extremely little geometry. It is basically the same problem as sorting. Anyway, here I am, about 40 years later, working on a very different kind of convex hull.)

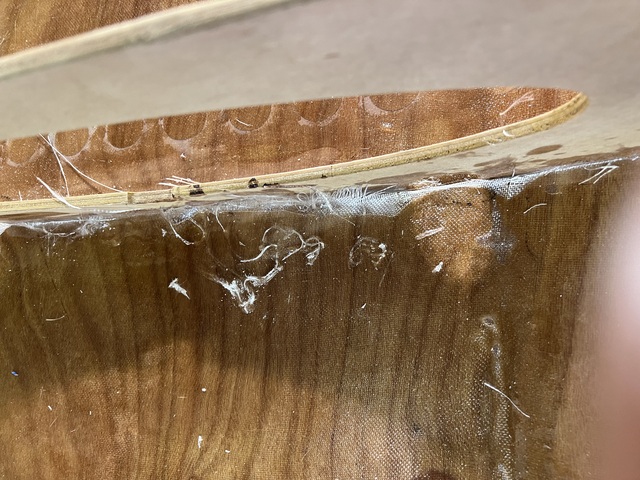

But the interior of the boat is definitely not convex. The interior is interrupted by vertical frames, so the fiberglass needs to go up to but not past those frames. And the ends of the boat, come together in V shapes, and the fiberglass has to conform to those shapes. And fiberglass is very floppy, so it is tricky to keep excess fiberglass from flopping into the parts that are being epoxied.

Second, the seam between the bottom and first panels was, per instructions, covered with wet epoxy. So getting the fiberglass smooth, with the angles, and the frames, and the V shapes at the end of the boat, oh, and the somewhat rough interior catching the fiberglass, AND the clock ticking, while the epoxy in the seams was drying — all that made for a very difficult and somewhat frantic epoxying session.

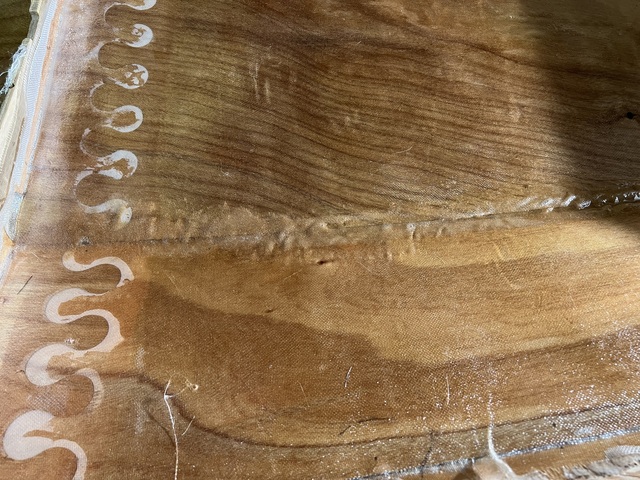

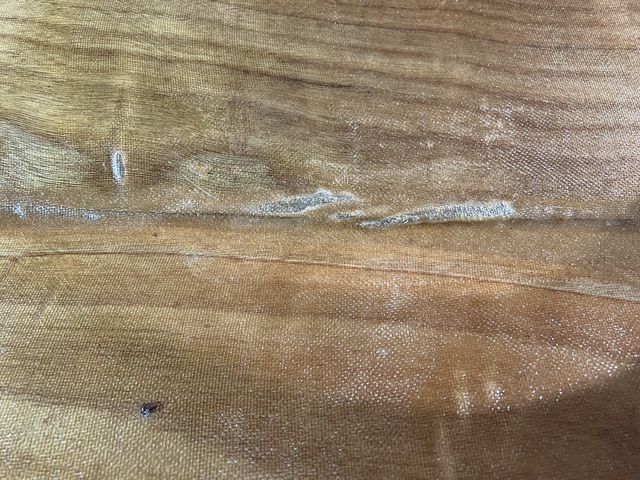

Here is the interior after all the glass was epoxied:

It's kind of a mess. Lose strands of fiberglass all over the place,

blisters, and wrinkles.

My plan is to use the heat gun and a knife to carve out the

defects, and then apply a patch.

Do you see? You see why this is taking so long? Every time I spend N hours doing something to this boat, I have to spend about 5 x N hours cleaning up my incompetent work.