September 1, 2022: It's cold and windy, and we are leaving

tomorrow. We are going back to Somerville, and Hannah is going to LA

for a wedding and then back to Brooklyn. We will chauffeur Eloise back

to Brooklyn next week.

I haven't posted anything for a month, because it's all been the same: heat up parts of the interior fiberglass that I botched, cut it out, put in a patch, cover with epoxy. That's almost done. It really isn't pretty. It looks like a Frankenstein boat, with all the patches and seams, but hopefully the fiberglass and epoxy will do their job and keep the wood protected.

Next, I need to install the seats, at the ends and middle of the boat. And the box that holds the centerboard (the centerboard trunk) needs to be assembled and installed. I needed to deal with mold, as with the frames, so the sanded and bleached pieces are drying outside right now.

But I already see the next problem. The center frame is bent. As

with the breasthooks, the boat is

slightly too narrow, and that resulted in the frame being bent.

The top of the frame points aft (toward the back of the

boat), and the centerboard trunk won't fit right. The frame and the

bottom panel should form a right angle, and because of the bend in the

frame, the angle is a bit more than 90 degrees, so the centerboard

trunk doesn't line up right.

CLC support tells me to use straps or something similar to apply pressure and bend the frame into shape. Braces. For my boat. I'm trying to figure out how and where to place the boat in the basement, where to attach the straps, so that everything stays in place while the frame is gradually modified. I've also written to the CLC forums for advice.

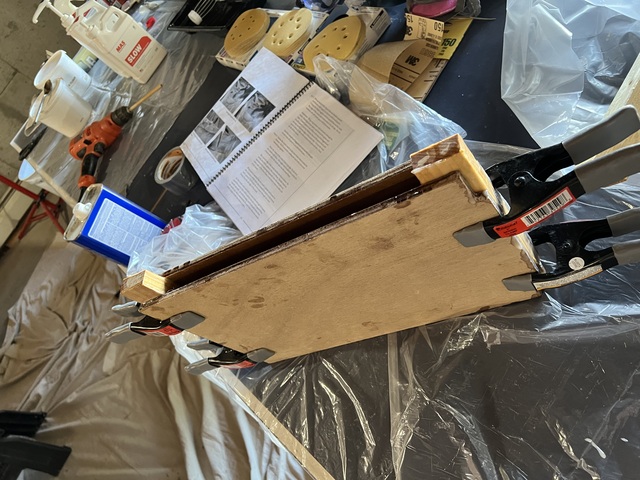

October 14, 2022: I got lots of ideas from the CLC forum. One idea was to attach a strip of lumber to the bent frame, to straighten it out, allowing the centerboard trunk to line up. I tried that idea using clamps, and it seems to work!

Here is the frame and centerboard trunk without clamps. Notice that

the top notch of the centerboard trunk does not reach the cutout in

the frame.

And with clamps. They do meet!

So I have a plan. I still need to assemble the centerboard trunk, and finish the interior — lots of sanding and epoxying for all of that. Once that is done, I should be able to install the centerboard trunk permanently, (using epoxy and screws instead of clamps).

January 16, 2023: The boat is back in the basement for the

winter. More sanding. More epoxy. This is right after the 2nd coat of

epoxy.

February 12, 2023: More of the same. Here is a picture, but it

really looks the same. More sanding, more epoxy.

In related developments, I'm also continuing to sand and epoxy the

pieces of the centerboard trunk.

And today's weather is bright and sunny, high in the low 40s.

Or that's what I think, anyway. The CLC kit ships with large containers of epoxy and resin. I have had to buy a second pair of the same size. And a third, smaller pair. I hope I don't run out.

I have a very heavy hand with epoxy. The boat should weigh 100 lbs. when done. I suspect that mine will be quite a bit more, maybe 20-30% more. I use epoxy to cover mistakes, like the badly fiberglassed interior. I use excess epoxy because I am paranoid about missing spots, and water coming into contact with wood. I use more coats of epoxy than I should because there were spots where the epoxy took on a weird texture, so I figured more sanding and more epoxy would fix the problem, (maybe it did a little). Basically, I throw epoxy at any problem I encounter. So this boat has a LOT of epoxy on it.

Expert makers of this sort of boat go with a natural finish,

just varnish on top of the epoxy. I had been thinking about

painting, as a way to cover my many, many mistakes. But you know

what? I'm just going to own the flaws. I mean, look at this (from

the CLC website). This is the boat I'm building, in its rowboat

configuration:

Mine won't look this good, but a natural finish, with all the flaws visible, will remind me of building the boat. Good times, good times.

It's March 29, 2023. It isn't very cold, but the lake is still

frozen.

I have a number of small pieces of wood that I need to epoxy on all

sides. These are spacers, that separate the two sides of the

centerboard trunk.

I would normally cover three sides, and then another day, cover the side that was face down while the other three sides were setting. I thought I'd save time. So I covered all four sides, and set the pieces on pieces of nylon rope. I expected that the side lying on the rope would not be smooth, but that I could sand it out later. These pieces are separators between other pieces of wood, so they should be sanded anyway before being epoxied in place.

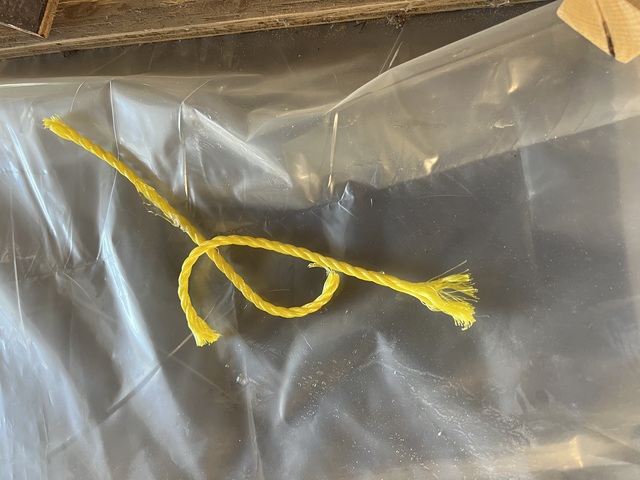

Here is the rope I used.

Of course it didn't work. I was able to easily remove the

rope from the dried epoxy. And as expected, the surface was

uneven. So I started sanding. But instead of the hard surface that

results when epoxy sets normally, there was this softer surface. The

nylon from the rope was apparently dissolved into the setting epoxy,

and sanding it created this goopy snot-like stuff.

I was finally able to clean off the surface completely, down to the wood, and I epoxied it again (more epoxy — yay!), no nylon rope involved this time.

Next day. I reapplied epoxy to the spacers, and assembled the

centerboard trunk. I'll return in a few days to see what went wrong.

April 4: Not perfectly assembled, because the spacers moved a

bit. But it should be okay. I trimmed the spacers and applied some

thickened epoxy to fill in gaps between the sides and spacers.

It's May 2, 2023. The lake ice melted last month, and today we had a

brief hailstorm. The first one I've ever seen here.

Alert readers will recall that I made the hull slightly too narrow, and that the frames are bent, and this causes the centerboard trunk to not fit. And that I worked out a fix involving a strut to shape the frame. (If you aren't an alert reader, just scroll up a bit.)

So today was the day that I finally played orthodontist. And boy was I organized. I planned out everything:

First, I put the boat on the floor, figuring that it would be

better to sit in the boat to do this work, instead of reaching across

from the sides. (This is the first time I've sat in the boat!)

And it all went nearly perfectly. Now about step 14: I was going to

use my drill to tighten the screws. But this was the moment that,

after four years of trusty service, my drill decided to seize up. I

could not turn the turny thing that loosens and tightens the teethy

things that hold the drill bit (or chopstick) in place.

It was working fine, a few minutes earlier, when I was mixing epoxy, but now it was stuck. Fortunately, I had screw wax handy (so organized!), and coating the screws with the wax, combined with my precision-drilled pilot holes, I was able to put in the screws manually.

And here we are:

May 3, 2023: With the middle frame now reshaped, the centerboard

trunk should now fit. Alert readers will recall that the whole point

of all this work on the frames was because the centerboard trunk did

not fit at all. So now that the frames are closer to where they should

be, the centerboard trunk should fit. It's in the right ballpark, but

the notches in the frame and the trunk don't quite fit.

I used the shinto rasp to sand the notches on both parts. It now

fits, but this sanding also introduced some gaps between the trunk and

frame.

I'll ask the CLC forum about those gaps, but I'm guessing that I'll need to glue in some shims.

The bottom of the trunk does meet the bottom panel nicely. Next, I needed to make sure that the other end of the trunk is aligned along the center of the boat. This needs to be really precise, otherwise the bottom of the boat, including the keel, will be at an angle to the centerboard, which can't be good.

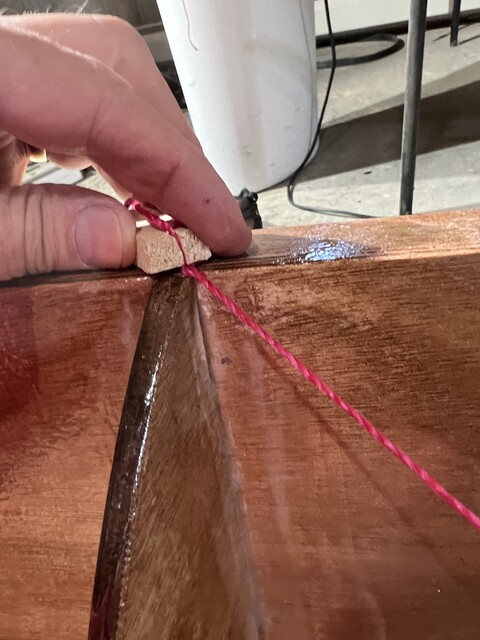

Finding the exact centerline isn't trivial. The bottom panel isn't

quite flat. The seam where it meets the next panel isn't a straight

line. The manual suggests checking that the center of the top end of

the trunk is equidistant from matching points on the left and right

sides of the hull (the "ears" on either side of the forward frame):

I put a nail into the top center of the trunk, and tied some string

around it. Then I stretched the string to each of the ears, and

compared the distance on the left and right sides. I adjusted the

angle of the trunk until the distances matched.

With the trunk angle worked out, I marked the trunk's position on

the bottom panel.

May 4, 2023: The back frame is really bent. And it's short, so bracing it isn't as successful as with the middle frame. I clamped on a strut, and the frame doesn't straighten completely. The seat that fits over the frame has two slots cut out (for the "ears") of the frame, and it really doesn't fit well right now. I will straighten the frame as best I can, but will probably need to do some shaping of the seat. I think (based on some measurements) and hope that the exterior of the boat is more symmetrical.

Anyway, here is the rear frame, with its strut, epoxied and

clamped. I'll screw it in on my next visit.

May 9, 2023: I am neck deep in dealing with previous errors. The boat is too narrow, so the frames are bent, so the seats don't fit onto the frames quite right. I straightened the frames as much as I could, so it is now time to fit the seats.

There are three seats, one at each end of the boat, and one in the

middle. Of these, the seat at the front (bow) end fits best, because

that frame is not very bent. But the seat doesn't fit well enough.

It appears pretty symmetrical. The square cutout in the seat is where

the mast will go. It does appear to be right in the center. (That pink

string marking the center looks offset slightly to the right of the

picture, but it doesn't look that way in real life.)

But the seat doesn't rest against the frame. Here is a view from below

the seat:

Also, the whole seat is too far forward. The front of the seat slots

are tight against the frame:

But the rear of the seat slots have a gap:

In other words, the narrowed hull pushes the seat too far back, and that prevents it from settling down against the top of the frame. I think that I will widen the slots on the seat. I've asked about this on the CLC forum. My guesses about how to fix my many, many errors, have been pretty good, usually not too far off from what the wise people of the forum recommend. CLC support is also on the case, (thanks Nicky!).

It's getting to be time for another visit to Mark. I'm going to need his tools again, to trim the slots. I'll also need to borrow a router, to cut a slot in the bottom of the boat for the centerboard.

Speaking of which, the centerboard actually does fit in the

centerboard frame!

May 10, 2023: On the CLC forums, Laszlo suggested cutting out a cardboard template to match the seat, fit it onto the frames, trim the template to fit, and then apply those changes to the seat. This is similar to what I did with the breasthooks. Nicky, at CLC support, suggested just grinding down the seat where necessary.

The CLC forums provide useful advice. But not just advice, it's

also a maternal pat on the head, "there, there, it will be fine." Even

experienced builders find that things don't fit, and they add shims,

sand things down, and in general, just do what is necessary to get all

the parts to fit together. I started to think about my building this boat as

one of those slow thrillers,

like The

Conversation, in which the protagonist's previous actions, and

psychological flaws accumulate, and interact, and finally result in

his complete emotional destruction.

(BTW: Thanks, Paramount, for Rosebud-level spoilers in that trailer.)

I forgot to temporarily include the breasthooks while wiring up the panels. That resulted in the hull being an imperceptible 1.5% too narrow. This caused the frames to slightly buckle. I only noticed that when I first tried to fit the seats onto the frames. I expected this to continue to the point that I finally launch the boat and it collapses and sinks as soon as it touches the water.

But no, it's more Don't Worry, Be Happy.

I decided to go with Nicky's suggestion. First, I think the bow seat was really close to fitting, needing corrections measured in small numbers of millimeters. Second, cardboard isn't as stiff as wood, and I suspected that the cardboard sagging would result in inaccuracies. Also, there would be errors in translating the changes to the actual seat (as with the breasthooks).

The grinding worked! It was a lot like getting the keel to fit. Figure out where the seat was contacting the hull or frame in the wrong place, sand that down, repeat. Finding those contact points was not easy, but with enough close inspection, and pushing and prodding to see where the seat moved, and where it was stuck, I did figure it out.

Putting some weight on the seat (the box in this photo), reduced

the gap between the seat and frame. Here's the gap early on:

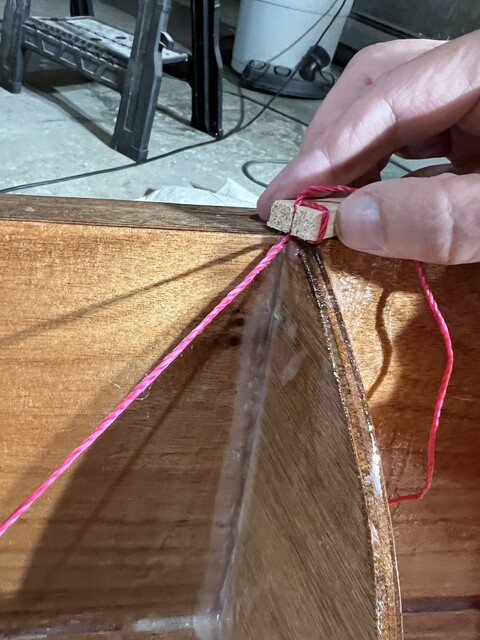

More dentistry analogies: I just had a crown put on a bad

tooth. The dentist checked the fit by having me grind a piece of

carbon paper (to see where the carbon goes on the crown), and using

floss. That's basically what I did here. Except that instead of

carbon paper, I wiggled the seat to see where it was sticking. This

photo shows the string I was using as floss.

By the way, the Sjöbergs Smart Vise was incredibly useful for this

work. I put the seat into the vise, and then sanded using the shinto

rasp, or a piece of the adhesive sandpaper (convenient because I

could get long strips of sandpaper to fit into the slots on the

seat). Oh yeah, using all the tools.

And here it is:

This was all for the bow seat, the one in front. The middle and

rear (stern) seats fit much worse initially, but surprisingly, they

were much easier to grind into shape. I mostly just sanded the slots

where they contacted the frames, and they then fit nicely.

I finished up today by drilling holes in the middle frame and through the bottom of the boat for attaching the centerboard trunk later.

And now, it is time to clean up, and move back to the larger work area.

May 11, 2023: The basement is now empty (although there's a lot of

sawdust to be vacuumed). It is ready for use as a cat loo during the summer.

I hope this is the last time that I had to pick up the boat by one

side and carry it through the door to the lower garage. Thanks to a

couple more tons of epoxy, it's getting harder to do that maneuver. If

all goes well, I'll take the finished boat out the garage door, to the

lake this summer, and never have to move the boat into the basement

again.