Now that the hull is wired, the next step is to glue the panels and frames. That will put everything together permanently, and start making the hull waterproof. I need to mix epoxy with various consistencies, and apply it between the wires. This shouldn't be too difficult since I learned quite a bit about epoxy when gluing the panel halves together.

First, I needed a new work area. I had been working in the lower garage. But it's getting colder in New England, and the epoxy requires a room temperature of at least 60F. Getting the boat out of the garage, and into the adjacent basement room was tricky. The boat won't fit through the door, unless I tip it on its side. Then I have to dodge columns to get it into its new work area.

I bought a dolly, but that didn't work very well with the boat tipped up on its side. I had to hold the boat up, and I couldn't prevent the dolly from scooting out from under. But the boat isn't that heavy, so I just picked it up and carried it.

And here we are:

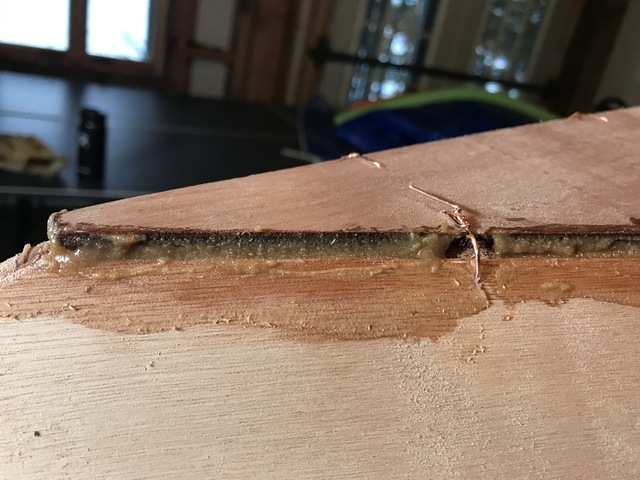

I need to glue the bottom panel to the next panels up. For some reason, those panels are called "garboards". I get to talk like a pirate when discussing my boat. Garboards. (I'll bet it's actually pronounced "gabbards".)

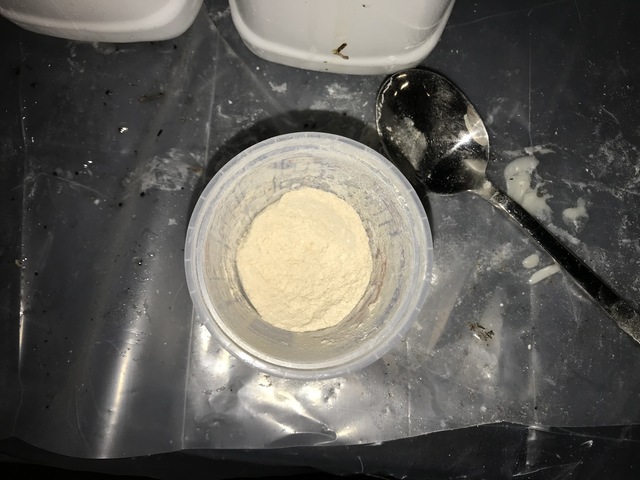

My previous gluing experience started with epoxy combined with

silica powder to a "mustard" consistency. This time, the manual says

I was aiming for "peanut butter", using wood flour (basically, very

fine sawdust) and silica, mixed in a 3:2 ratio.

I then needed a tool to dab the peanut buttery epoxy into the seam

between the bottom panels and garboards. (Love saying that.) That seam

is maybe 1/4" wide, and similar depth. I have all these wood scraps,

and I could have whittled a tool of the right shape. But I had stopped

at a supermarket, and picked up sushi for lunch. Which came with

chopsticks, the kind you pull apart. These were perfect for the job at

hand. Square at one end (where you pull them apart), and narrower and

round at the other end. This turned out to be a really excellent tool

for the job.

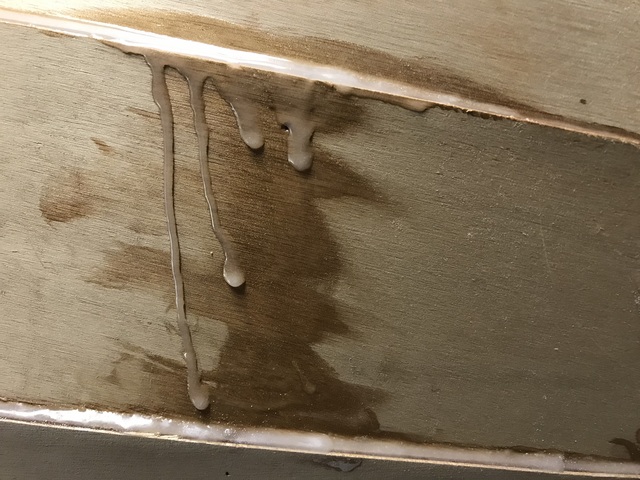

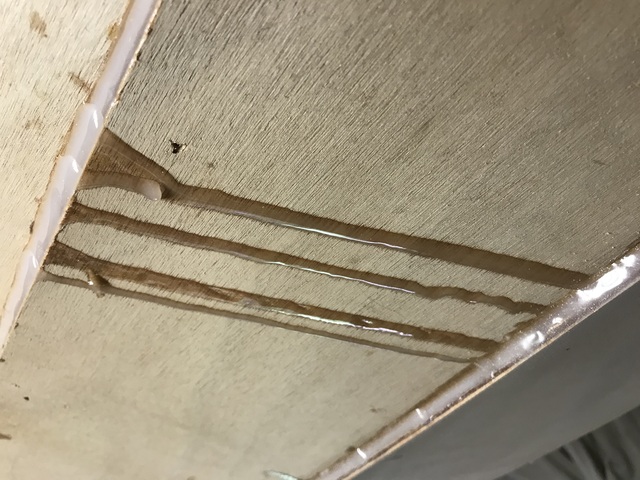

Well. After a few months of cold temperatures in my work area, and,

..., there was something else, what was it, ..., oh yeah, the global

pandemic, I've gotten back to finally finishing up this phase. The

gluing is done, and it was a pretty sloppy job, if I say so

myself. Lots of runs of epoxy.

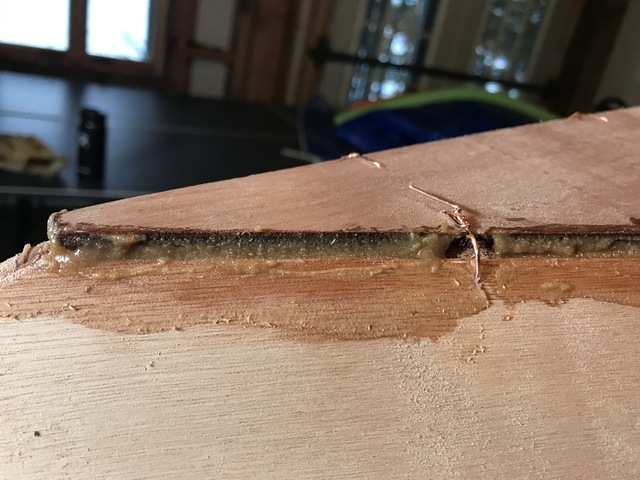

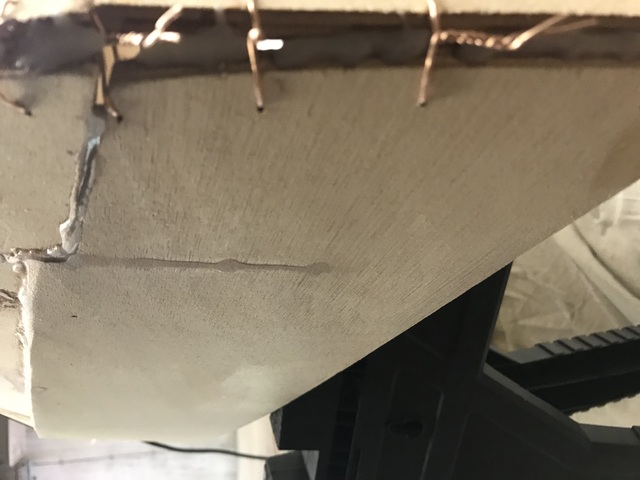

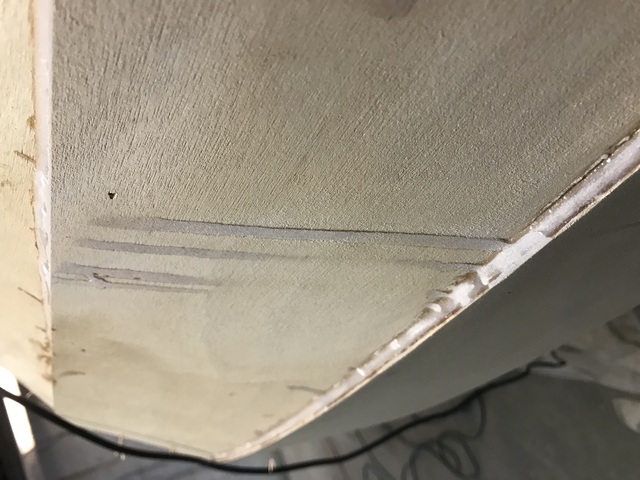

But a few hours of sanding took care of that. It isn't pretty,

because the runs left marks, but the surface is smooth now. Here is

one before/after comparison:

I don't want to sand too far, and make the hull significantly thinner,

so I'll leave it like this.

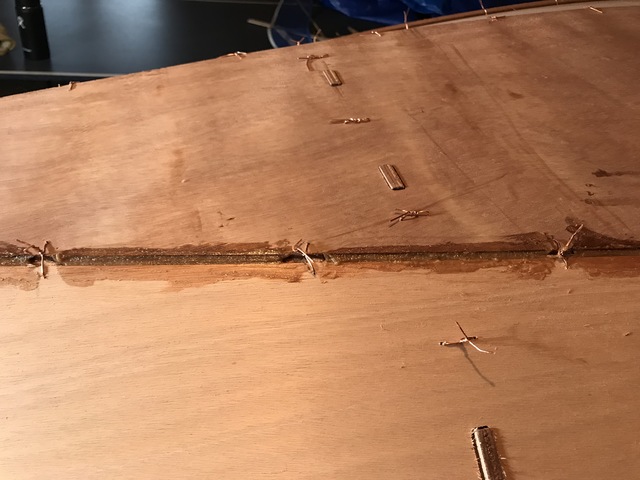

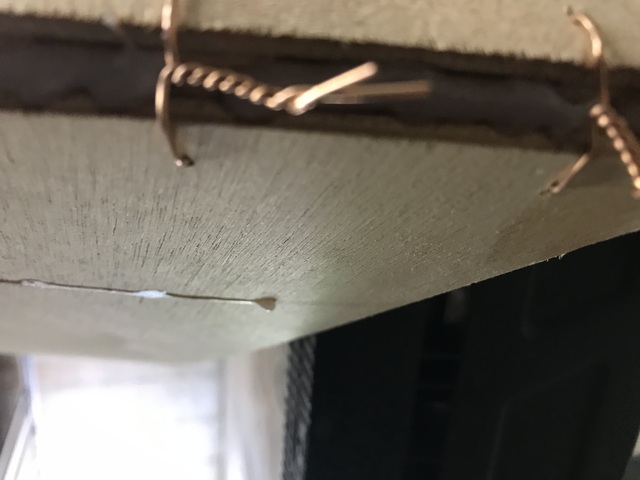

Still more to do on the stems (the front and rear edges of the boat,

where the panels come together).

Here is the same area pre-sanding: