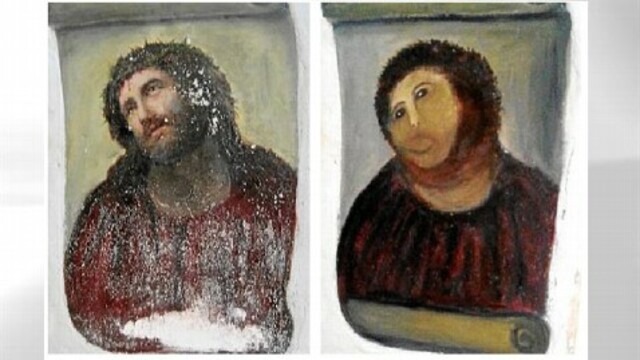

Yes, still at it. Still building the boat. But slowly. And yes, still gluing the hull, more than a year later.

I was chatting with some people on the CLC forum about the mess I

created. One guy posted some very useful advice — use this tool,

here's how — and posted photos of his own boat. His was beautiful and

perfect. No runs. The epoxy between the boards was shaped

perfectly. The fiberglass was applied perfectly. it melded into the

seams and glue perfectly. His work, compared to mine, is basically

this:

That guy can go for a "bright" finish, i.e., apply varnish and have a beautiful wooden boat, that looks like a wooden boat. I will need to apply paint to hide the amateurish work.

... If I get to finishing the boat, that is.

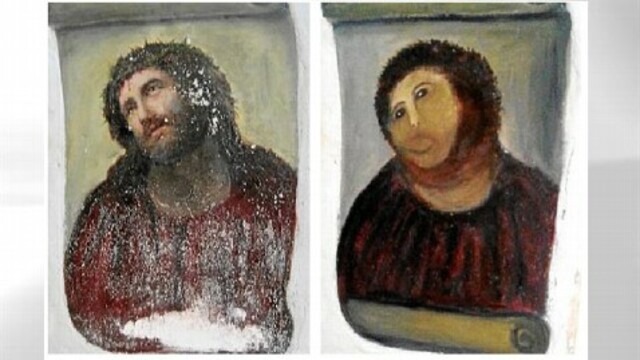

Audrey and I were moving the boat to the warmer part of the

basement, for THIS winter's work, and I dropped my end. The stem

(where the boards come together) popped apart.

For now, I've wired the boards back together. Back to the forums for more advice.

After I dropped my end of the boat, and busted the stern, and after about 45 seconds of staring in disbelief, my first reaction was that I should sand off the epoxy, wire up the panels, and glue it again. But because my confidence in my own intuition about this work with physical objects is so low, I did go to the CLC forum, to ask what to do. And I wasn't far off! Instead of sanding off the epoxy, just sand it down to roughen the surface.

So I sanded down the epoxy, and then got the shop vac, and proceeded to use it in reverse, to blow air out of it, to disperse the sawdust created by the sanding. (Ed. note: Why not vacuum up the dust?) And it sounded like a machine gun going off. There was something being blasted all over the place.

I shut off the shop vac, and noticed that there were acorns, all over the place.

You see, there were acorns, in the shop vac.

As often happens when the weather turns cold, mice come inside, and some particularly clever mice decided to store their acorns in my shop vac. Which means that they climbed up onto the shop vac, to the place where the hose attaches for the vacuum, (which is open, because the hose is plugged into the other opening right now), and deposited their acorns inside. Stupid mice. How did they think they were going to extract their acorns?

Well, problem solved, I guess, those acorns are now all over my

basement.

I cleaned up the acorns, and glued the boards. I'll see how the

repair goes on my next visit.

We got our first motorboat in 2003, our first summer on the lake in our own house. We bought a cheap, used one, because everything about owning a motorboat was alien to us: Having a trailer hitch. Having a trailer. Having a thing to tow on the trailer. Driving with a trailer, secure in the knowledge that the trailer hitch will come loose and the boat will end up careening all over the road, creating havoc and mayhem. Or that we'll be going downhill, and the boat will somehow plummet through the back of the car into our heads. Maneuvering the boat while driving backwards. Getting the boat into the water. Getting the boat out of the water. We weren't at all sure that the benefits of having a boat on the lake would outweigh these concerns. We weren't sure that one of our new mechanical objects would not kill or maim us.

And we learned the lessons slowly: It is a bad idea to put the boat in the water if you haven't screwed in the plug at the back of the hull, because water goes in through the hole that should have been plugged, and the boat sinks. It is actually impossible to put the boat in the water if the straps holding the boat to the trailer haven't been removed. Don't run out of gas while the boat is on the lake. Don't let the ropes break, the ones that tie the boat to the dock. Don't go over rocks that are just barely submerged and therefore invisible.

Building a boat also provides lessons. My latest: You know that chopstick that I used as a drill bit, to mix epoxy and resin? If you finish mixing resin, and you leave the drill, with the chopstick covered in epoxy, next to the plastic container of resin, just barely touching it, and then you go away, and then you come back weeks later, and then turn on the drill to make sure it's working — well, just don't do that. The epoxy weakens the plastic wall of the container, so what happens, you see, is that you rip open the container and resin starts pouring out.